|

Strain

Gauge Testing Compliments Our Analysis Services Perfectly Strain

Gauge Testing Compliments Our Analysis Services Perfectly

After manufacture test techniques can be used separately or in

conjunction with finite element analysis. It is an essential tool for

failure investigations or validation of design.

|

|

DYNAMIC 'HAMMER' TEST

Equipment

struck with a rubber hammer will vibrate at its natural frequencies.

This response will be seen by the strain gauges and sensors. A

spectrum analysis of the test signals will yield the frequencies

associated with the natural modes of vibration. Damping

characteristics can also be measured in this way. Equipment

struck with a rubber hammer will vibrate at its natural frequencies.

This response will be seen by the strain gauges and sensors. A

spectrum analysis of the test signals will yield the frequencies

associated with the natural modes of vibration. Damping

characteristics can also be measured in this way.

|

|

IN-SERVICE TESTING

The data

acquisition equipment and computer can be installed at any location

and is self powered. The photo opposite shows an installation in a

railway vehicle. Testing does not necessarily mean that equipment

needs to be taken out of service. The data

acquisition equipment and computer can be installed at any location

and is self powered. The photo opposite shows an installation in a

railway vehicle. Testing does not necessarily mean that equipment

needs to be taken out of service.

|

|

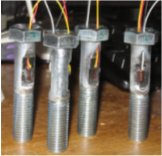

DESIGN AND CALIBRATION OF STRAIN GAUGE BOLTS

After disappointing performance with commercially available bolt

sensors MoreVision devised and produced special test bolts by introducing flats on the shank of the

bolts and attaching standard linear gauges (photo on the left). The

bolts were calibrated in a laboratory load cell shown in the photo on

the right.

|

|

BOLT RELAXATION TEST

Bolted joint performance is a common source of problems for mechanical

engineers testing a jointed assembly can help us understand poor joint

performance. Preload in bolts can be measured using load cells or

strain gauged bolts. It is possible to obtain a preload/torque diagram

and joint relaxation over a given time period.

|

SIGNAL PROCESSING AND ANALYSIS

Once data has been gathered from test the process of analysis of test

results and signal processing can begin. |