Terminology

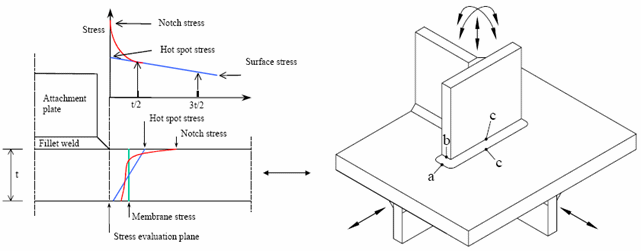

Local nominal stress: Nominal stress including macro-geometric effects, concentrated load effects and misalignments, disregarding the stress raising effects of the welded joint itself.

Structural stress: A stress in a component, resolved taking into account the effects of a structural discontinuity, and consisting of membrane and shell bending stress components.

Structural discontinuity: A geometric discontinuity due to the type of welded joint, usually found in tables of classified structural details. The effects of a structural discontinuity are (i) concentration of the membrane stress and (ii) formation of secondary bending stress.

Local notch: A notch such as the local geometry of the weld toe, including the toe radius and the angle between the base plate surface and weld reinforcement. The local notch does not alter the structural stress but generates non-linear stress peaks.

Notch stress: Total stress at the root of a notch taking into account the stress concentration caused by the local notch. Thus the notch stress consists of the sum of structural stress and nonlinear stress peak.

Notch stress concentration factor: The ratio of notch stress to structural stress.

Hot spot: A point in structure where a fatigue crack may initiate due to the combined effect of structural stress fluctuation and the weld geometry or a similar notch.

Hot spot stress: The value of structural stress on the surface at the hot spot (also known as geometric stress or structural stress).

Figure 1 – Hot spot positions a, b and c and explanation of hot spot and notch stresses

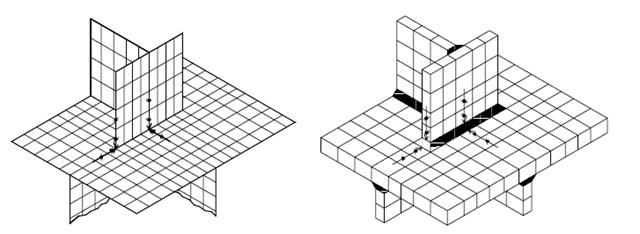

Figure 2 – Determine hot spot stress by extrapolation of FE result

Determine Hot Spot Stress for Fatigue Assessment. t is not necessary to model the weld profiles for the following reasons:

• Actual welds may have a variety of profiles and it is not possible to model every variant.

• The SN curve includes the notch effect at the weld toe based on a statistical assessment of a many fatigue tests.

• Inclusion of the weld makes determination of the hot spot stress more difficult to determine. Compare the stress along paths with and without the weld profile modelled.