Pipe flow/friction factor calculations

Description

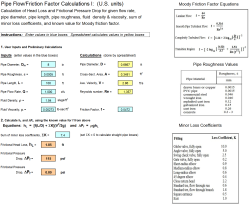

Calculation of Head Loss and Frictional Pressure Drop for given flow rate, pipe diameter, pipe length, pipe roughness, fluid density & viscosity, sum of minor loss coefficients, and known value for Moody friction factor. In both S.I. and US

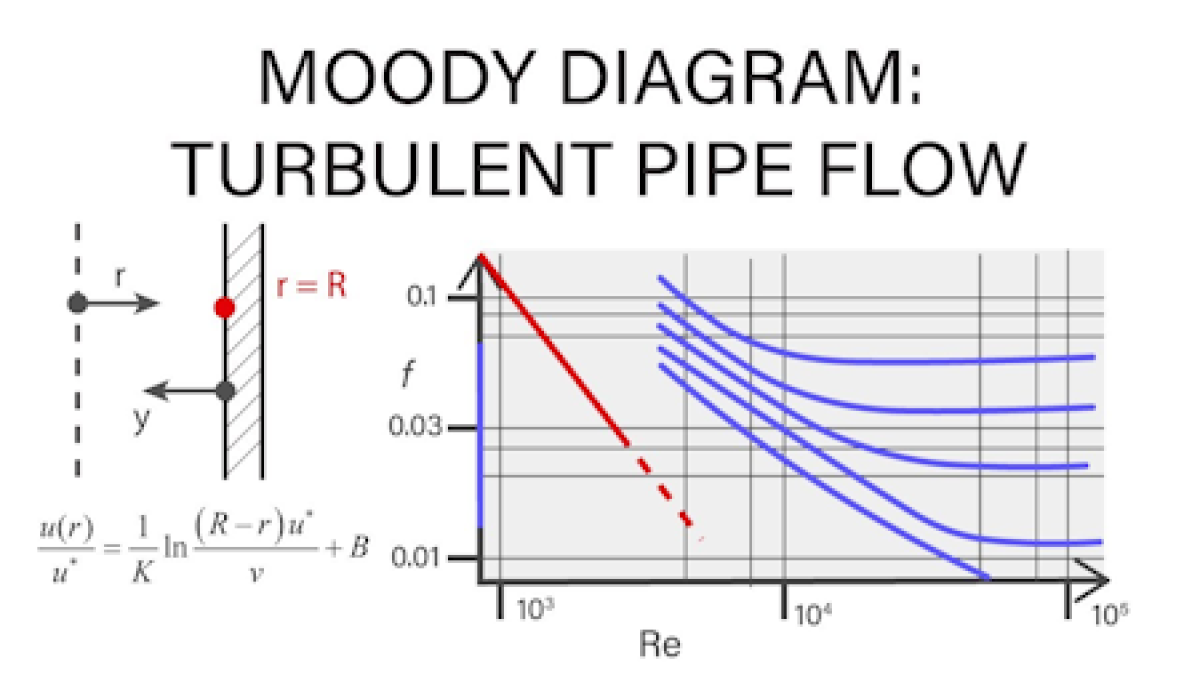

This calculation is based on the principle of energy loss in pipe flow due to friction and minor losses. When fluid flows through a pipe, it encounters resistance that causes a drop in pressure and energy. There are two main types of energy losses:

- Major losses (friction losses): These occur due to friction between the fluid and the pipe walls along the entire length of the pipe. The rougher the pipe surface, the greater these losses.

- Minor losses: These occur at specific locations like bends, valves, contractions, or expansions in the pipe system where the flow pattern is disturbed.

The calculation uses the Darcy-Weisbach equation along with the Moody friction factor to determine how much energy (expressed as "head loss") or pressure is lost as fluid moves through a pipe system.

The key factors affecting these losses are:

- Flow rate (how fast the fluid is moving)

- Pipe diameter (smaller pipes create more resistance)

- Pipe length (longer pipes mean more friction)

- Pipe roughness (rougher surfaces create more friction)

- Fluid properties (density and viscosity)

- Minor loss coefficients (for valves, bends, etc.)

This is a fundamental calculation in hydraulic engineering used for designing everything from building plumbing systems to industrial pipelines, water distribution networks, and oil transport systems.

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.