Pneumatic pressure test - restricted distance

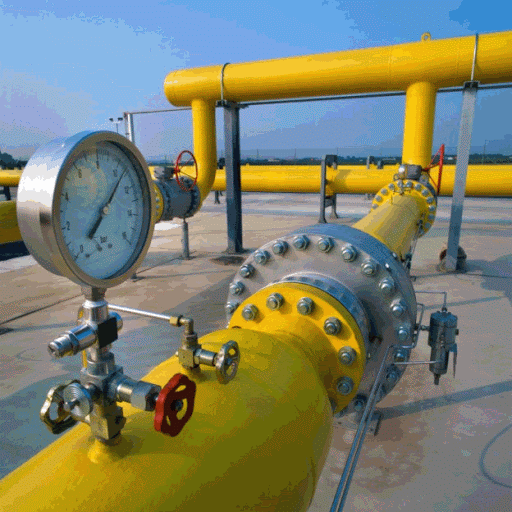

Description

Although hydro test is more safe and the prefered method in the piping and pressure vessels industires, pnumatic pressure test is used when the system can not be drained and dryed.

The program calculates safe distance in two methods:

1- NASA Glenn Research Safety Manual

2- ASME PCC-2 - Art 5.1 - 2008

For pneumatic pressure testing, safe distances are typically determined based on the stored energy within the system and the potential consequences of a sudden release of pressure. The safe distance will depend on factors such as test pressure, size and volume of the system, and the surrounding environment.

To determine a safe distance, you can follow these general guidelines:

-

Perform a risk assessment: Identify the hazards associated with the pneumatic pressure test, such as the potential for equipment failure, pressure release, or projectiles. Consider the potential consequences of these hazards, including injuries to personnel, damage to equipment, or environmental impacts.

-

Identify mitigating measures: Develop and implement measures to reduce the risk associated with the identified hazards, such as proper equipment maintenance, inspection, and testing, as well as appropriate pressure relief devices and barriers.

-

Calculate the safe distance: While there isn't a standardized formula for calculating safe distances for pneumatic pressure testing, you can use industry best practices or company-specific guidelines to estimate a safe distance. In some cases, organizations may use a minimum distance based on the diameter of the equipment being tested, such as using a distance of 2 times the diameter or a fixed minimum distance (e.g., 15 feet or 5 meters).

-

Establish exclusion zones: Based on the calculated safe distance, establish exclusion zones around the test area, and restrict access to authorized personnel only. Ensure that appropriate signage, barricades, and other safety measures are in place to prevent unauthorized entry into the test area.

It is essential to consult relevant standards, industry best practices, or company-specific guidelines to ensure the safety of personnel and equipment during pneumatic pressure testing.

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.