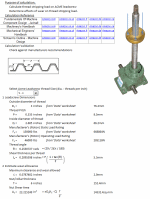

Screwjack effects of wear on thread stripping load

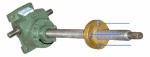

Description

Purpose of calculation:

Calculate thread stripping load on ACME leadscrew

Determine effects of wear on thread stripping load.

This calculation is featured as a case study.

Calculation Validation

Check against manufacturers recommendations

Select Acme Leadscrew thread Size (dia. - threads per inch)

- Leadscrew Dimensions

Outside diameter of thread

Thread Pitch

Inside diameter of thread

Manufacterer's (Roton) Static Load Rating

Manufacterer's (Roton) Operating Load Rating

Thread angle

Shear thickness per thread

- Estimate wear allowance

Maximum clearance and wear allowed

Nut/collar thickness

Shear Area

- Nut material properties and nut shear strength calculation

Calculated operating load

Correlation between calculated and manufacturers value

- Calculate normal loading with maximum allowable load nut wear

Force on leadscrew

Operating load

- Calculate wear for nut thread stripping

Critical Clearance/Wear Limit for nut stripping

Amount of wear for nut stripping

- Estimate Wear

Bearing stress

Rubbing Distance

Surface Hardness (Brinell Hardness in kg/mm2 convered to psi)

Wear Coefficients from ExcelCalcs Repository

Unlubricated wear depth in 6 months - Ref. Juvinall Eqn. (9.1)

Time to unlubricated load nut failure

Lubricated wear depth in 6 months

Time to lubricated load nut failureCalculation Reference

Fundamentals Of Machine Component Design - Juvinall

Machinery's Handbook

Mechanical Engineers' Handbook

Schaum's Outline - Machine Design

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.

Be the first to comment! Please sign in or register.

×