Adhesive Wear Rate Between Two Metals

Description

Purpose of calculation:

Determine the adhesive wear rate of two metals.

This calculation is featured as a case study.

Calculation Reference

- Wear Coefficients - Metals Section IV of 10, E. Rabinowicz.

- Fundamentals of Machine Component design, Juvinall

Calculation Validation

Check against calculation in Ref. 2

Calculation Procedure

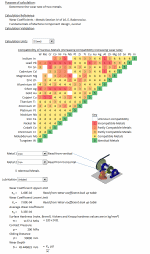

Compatibility of Various Metal combinations (increasing compatibility increasing tendency to weld and increasing wear rate)- Indium

- Lead

- Tin

- Cadmium

- Magnesium

- Zinc

- Aluminium

- Silver

- Gold

- Copper

- Titanium

- Zirconium

- Platinum

- Niobium

- Iron

- Nickel

- Cobalt

- Chromium

- Molybdenum

- Tungsten

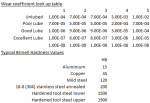

Wear Coefficient Lower Limit (of softer material)

Estimated Wear Coefficient (set between limits or calculate average)

Surface Hardness (note. Brinell, Vickers and Knopp hardness values are in kg/mm²)

Contact Pressure

Sliding Distance (often calculated as a velocity x time)

Wear DepthCalculation Reference

Fundamentals of Machine Component design, Juvinall

Machinery's Handbook 18th ed.

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.

Be the first to comment! Please sign in or register.

×