Shear end plate design as per EN 1991-1-8

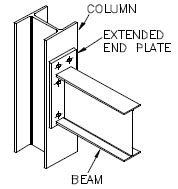

Description

sHEAR END PLATE DESIGN AS PER EN 1993-1-8

EN 1991-1-8, part of the Eurocode suite of standards, provides guidelines for designing steel structures subjected to shear forces. Specifically, shear end plate connections are often used to join beams to columns or other structural members, and their design is crucial for the stability and safety of the structure. The following is a summary of the key aspects of shear end plate design as per EN 1991-1-8:

-

Load Determination: Calculate the acting shear force, based on the applied loads and the corresponding load combinations as per EN 1990 (the Eurocode for Basis of Structural Design).

-

Plate Thickness: Determine the required thickness of the shear end plate to ensure it can withstand the applied shear force without failure. This is typically calculated using the material's yield strength and the safety factor.

-

Bolted Connection Design: Design the bolted connection between the shear end plate and the connected structural members. This includes selecting appropriate bolt types, sizes, and spacing, as well as determining the number of bolts required to safely transfer the shear force.

-

Bearing Resistance: Ensure that the bearing resistance of the connected structural members is sufficient to prevent local failure due to the applied shear force. This involves checking the material's yield strength and the safety factor.

-

Stiffness: Evaluate the stiffness of the shear end plate connection to prevent excessive deformation and ensure the overall structural stability. This may include the use of stiffeners or other means to increase the connection's rigidity.

-

Welded Connection Design: If the shear end plate is welded to the connected structural members, design the welds according to the Eurocode specifications for welded connections. This includes selecting appropriate weld types, sizes, and lengths, as well as considering the material's weldability.

-

Durability and Corrosion Protection: Consider the exposure conditions of the shear end plate connection and apply appropriate corrosion protection measures, such as galvanizing or using corrosion-resistant materials, to ensure the connection's durability.

-

Detailing: Provide clear and accurate detailing of the shear end plate connection, including the required dimensions, bolt types and sizes, weld specifications, and any additional components, such as stiffeners.

In summary, the design of shear end plate connections as per EN 1991-1-8 involves considering various factors, such as load determination, plate thickness, bolted and welded connections, bearing resistance, stiffness, durability, and detailing. Properly designing shear end plate connections is crucial to ensure the structural stability and safety of steel structures.

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.