Lift Lug calc for Skid

Description

PLEASE NOTE: "Lift Lug calc for Skid" has links with "Weight & Bolting_lse.xls" These may be downloaded separately or together as a zip file.

LIFTING LUG DESIGN CALCULATION (SKID)

ITEM : C.I. SKID (A-6810)

PROJECT NO. C.I Injection system (A-6810) - Permas Field Substructure

Weight of component to be lifted

Component force acting on beam, F

Impact factor

SKID LUG SIZING

Distance from lug hole to edge of beam, k

Lug radius, rL

Lug thickness, tL

Lug base width, wL

Diameter of hole, d

Distance from lug hole to base, hL

Collar plate thickness, tcp

Collar ring diameter, Dcp

Clearance btw shackle & lug size

Lug thickness, tL

A = 42.9 mm 40

Lug radius, rL

C = 95.5 mm 70

Since A & C clearance against Lug size , Therefore the Lug is is

ACCEPTABLE

Per PTS Section 6.3

a) Lug hole diameter, d shall be Max of i) Dp + 3mm

ii) Dp X 1.05

b) Lug hole diameter, d shall be less than < (Dp + 6mm)

Dp = 33 result a)

b)

Hole,d

Diameter of hole, d btw 31.70 33 34.70

No of lug eye,

Maximum combined force acting on lug eye, Fc

LIFTING LUG MATERIAL & MECHANICAL PROPERTIES

Material used

Specified yield stress, Sy

Allowable bending stress, fbx.all ( = 0.66Sy ) _In Plane

Allowable bending stress, fby.all ( = 0.75Sy ) _Out Of Plane

Allowable tensile stress, St.all ( = 0.6Sy )

Allowable bearing stress, Sbr.all ( = 0.9Sy )

Allowable shear stress, Ss.all ( = 0.4Sy )

SHACKLES

Shackle rating ( S.W.L )

Type of shackle BOLT Type Anchor shackle G2130

Pin size, Dp

MAXIMUM SLING TENSION ON PADEYE Ts

FACTOR OF SAFETY F.O.S.

DESIGN LOAD:

SLING TENSION P = FOS Ts P

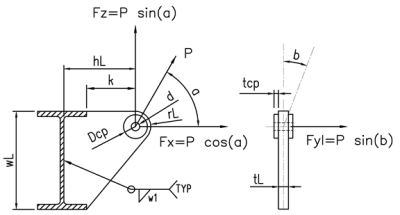

LIFTING ANGLE a

ACTUAL OUT OF PLANE ANGLE b

VERTICAL FORCE ON PADEYE Fz = P sin a Fz

OUT OF PLANE FORCE Fyl = P sin b Fyl

HORIZONTAL FORCE ON PADEYE Fx = P cos a Fx

Horizontal dist.PIN CL to N.A. exl

STRESS CHECK AT BASE

Moment Calc at distance , H

In Plane Moment My = ( FxH ) - ( Fzex l) My

Out of plane moment Mx = ( FyIhL ) Mx

Tensile Stress

Maximum tensile force, ft = Fz / [ tL wL ]

Allowable tensile stress, St.all ( = 0.6Sy )

Since ft < St.all, therefore the lug size is satisfactory.

Bending stress (In Plane)

Maximum bending stress , fbx = ( 6Mx ) / ( wL [(tL+tcp)^2] )

Allowable bending stress, fbx.all ( = 0.66Sy ) _In Plane

Since fbx < fbx.all,therefore the lug size is satisfactory.

Bending stress (Out of Plane)

Maximum bending stress , fby = ( 6My ) / [ tL +(2tcp)] [ wL^2 ] )

Allowable bending stress, fby.all ( = 0.75Sy ) _Out Of Plane

Since fby < fby.all,therefore the lug size is satisfactory.

Combined stresses,

U = St/St.all + fby/fby.all + fbx/fbx.all

Since U < 1, therefore the lug size is satisfactory.

SHEAR stress (In Plane)

Maximum SHEAR stress , fsx = Fx / [ wL tL ]

Allowable shear stress, Ss.all ( = 0.4Sy )

Since fsx < Ss.all,therefore the lug size is satisfactory.

Bending stress (Out of Plane)

Maximum SHEAR stress , fsy = Fyl / [ wL tL ]

Allowable shear stress, Ss.all ( = 0.4Sy )

Since fsx < Ss.all,therefore the lug size is satisfactory.

CHECKING VON-MISES CRITERIA

Sum of stress in X-PLANE fx = St + fby

Sum of stress in Y-PLANE fy = St + fbx

Therefore, average Shear stress fxy = SQRT [ (fsx^2)+(fsy^2) ]

Maximum Combined stress

Fcomb = SQRT [ (fx^2)+(fy^2)-(fx+fy+3fxy^2) ]

Allowable combined stress : Fcomb.all ( = 0.66Sy )

Since fsx < Ss.all,therefore the lug size is satisfactory.

STRESS CHECK AT PIN HOLE

Tensile Stress

Maximum tensile force, P

Cross sectional area of lug eye, At = [ 2 ( tL ( rL - d/2 ))] + [ 2 ( tcp (( Dcp/2) - d/2 ))] + [ 2 ( tcp (( Dcp/2) - d/2 ))]

Tensile stress, St

Allowable tensile stress, St.all ( = 0.6Sy )

Since St < St.all, therefore the lug size is satisfactory.

Bearing Stress

Maximum bearing force, P

Cross sectional area of lug eye, Ab = Dp ( tL + 2tcp )

Bearing stress, Sbr = Fbr / Ab

Allowable bearing stress, Sbr.all ( = 0.9Sy )

Since Sbr < Sbr.all,therefore the lug size is satisfactory.

Shear Stress `

Maximum shear force, P

Cross sectional area of lug eye, At = [ 2 ( tL ( rL - d/2 ))] + [ 2 ( tcp (( Dcp/2) - d/2 ))] + [ 2 ( tcp (( Dcp/2) - d/2 ))]

Shear stress, Ss

Allowable shear stress, Ss.all ( = 0.4Sy )

Since Ss < Ss.all,therefore the lug size is satisfactory.

Combined stresses,

U = St/St.all + fby/fby.all + fbx/fbx.all

Since U < 1, therefore the lug size is satisfactory.

WELD SIZE CALCULATIONS

Weld leg used,

Weld throat thickness used, tr

Filler metal material

Fillet weld joint efficiency, E

Welding stress for steel grade 43 ( E-43 ),

Allowable welding stress,Sw

Tensile Stress

Maximum tensile force,Ft

Area of weld, Aw = 2(tL+wL)tr

Tensile stress, St = [(Ft/Aw)]

Since St < Sw,therefore weld leg is satisfactory.

Shear stress

Maximum shear force,Ft

Shear stress, Ss = (Ft/Aw)

Allowable welding stress for steel grade 43 ( E-43 ), Sw

Since Ss < Sw,therefore weld leg dimension is SATISFACTORY.

Bending stress

Maximum bending force,Fb

Bending stress, Sb = [(Fb/Aw)]

Allowable welding stress for steel grade 43 ( E-43 ), Sw

Calculation Reference

Skid Design

Structural Steel Design

Lifting Lug

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.