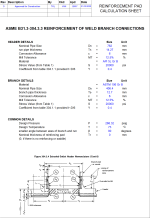

Reinforcement Pad Calculations

Description

The ASME (American Society of Mechanical Engineers) provides guidelines for calculating the reinforcement of weld branch connections, which are commonly used in piping systems to connect a smaller diameter branch pipe to a larger diameter header pipe.

The reinforcement calculation involves determining the minimum required thickness of the weld branch, which ensures that the weld is strong enough to support the applied loads and stresses without failure. The following steps are involved in the ASME reinforcement of weld branch calculations:

-

Determine the nominal wall thickness of the weld branch pipe: The nominal wall thickness is the thickness of the pipe wall excluding any corrosion allowance or tolerance. It is usually specified in the piping specifications.

-

Determine the design pressure and temperature: The design pressure and temperature are the maximum expected pressure and temperature of the fluid in the piping system. They are specified in the piping design specifications.

-

Determine the applicable piping code: The ASME B31 series piping codes provide guidelines for designing and constructing piping systems for various applications. The applicable code depends on the type of fluid, pressure, temperature, and other factors.

-

Determine the allowable stress of the material: The allowable stress is the maximum stress that the material can withstand without experiencing permanent deformation or failure. It is specified in the piping code based on the material properties, design temperature, and other factors.

-

Calculate the required thickness of the weld branch: The required thickness of the weld branch is calculated based on the applied loads and stresses. The ASME provides equations and tables for calculating the required thickness, which depend on factors such as the branch angle, branch diameter, and header diameter.

-

Calculate the reinforcement thickness: The reinforcement thickness is the additional thickness of material required to ensure that the weld is strong enough to support the applied loads and stresses. The ASME provides equations and tables for calculating the reinforcement thickness, which depend on factors such as the branch angle, branch diameter, and header diameter.

-

Verify the weld joint strength: The strength of the weld joint is verified by performing a weld joint efficiency calculation, which takes into account the quality of the weld, the welding procedure, and other factors. The weld joint efficiency is multiplied by the calculated reinforcement thickness to obtain the final required thickness of the weld branch.

The ASME reinforcement of weld branch calculations ensure that the weld branch connection is designed and constructed to withstand the applied loads and stresses and to prevent failure or leakage in the piping system.

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.