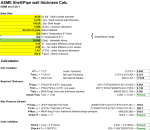

ASME Shell/Pipe wall thickness calculation

Description

Calculates wall thickness for shell or pipe according to ASME Sec. 8 Div.1. The program allows to select from few most popular materials, with a built-in allowed stress according to the work temperature.

The program checks both longitudinal and circumferential seams. The program checks code ratios validation.

The ASME Section VIII Division 1 standard provides guidelines for designing pressure vessels, including pipes and shells. Here's a general description of how a program might calculate wall thickness and check seams according to this standard:

-

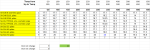

Material Selection: The user selects the material for the pipe or shell from a list of common materials. The material's properties, including its allowable stress, are built into the program.

-

Allowable Stress: The allowable stress of the material often depends on the working temperature. The program would have built-in data for how the allowable stress changes with temperature for each material.

-

Wall Thickness Calculation: The program calculates the minimum required wall thickness based on the internal pressure, the inside radius of the pipe or shell, and the allowable stress of the material. The formula used is typically something like:

t = PR / (SE - 0.6P)

where:

- t is the minimum required thickness,

- P is the internal pressure,

- R is the inside radius of the shell,

- S is the maximum allowable stress value of the material at the design temperature,

- E is the joint efficiency.

-

Seam Checks: The program checks both the longitudinal seam (running along the length of the pipe) and the circumferential seam (around the circumference of the pipe). The stresses in these seams must be within the allowable limits for the material. The longitudinal seam is often subject to greater stress due to the internal pressure, which is why the formula for wall thickness includes a term for longitudinal stress (0.6P).

-

Code Ratios Validation: The program checks that the calculated wall thickness meets the requirements of the ASME code. This includes checking the thickness-to-radius ratio and the thickness-to-diameter ratio, which must be within certain limits.

Please note that this is a simplified description and the actual calculations can be quite complex, especially for high-pressure or high-temperature applications.

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.