Single and Multi Miter Bend, max allowed pressure

Description

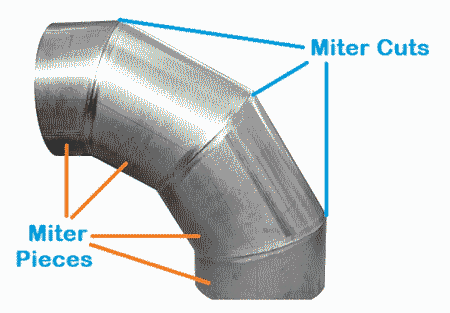

Miter Bends plays an important role because standard elbows are not easily available and economical for larger pipe diameters. Up to 3 deg. or less offset, the pressure calculation is done same as for straight pipe. ASME B31.3 304.2.3 provides design requirements and limitations for miter bends. The code provides two methods to calculate maximum pressure allowed: Single miter and multi miter bend, 2 to 5 miter cuts. The program provides common materials properties, factors tables and code's rules compliance check.

Miter bends are integral components in piping systems, particularly in scenarios where standard elbows are either unavailable or impractical due to larger pipe diameters. Their significance lies in their ability to efficiently redirect the flow of fluids or gases with minimal disruption to the system. When considering offsets of up to 3 degrees or less, the pressure calculations for miter bends align closely with those for straight pipe segments.

The design considerations and limitations for miter bends are outlined in ASME B31.3 304.2.3, which serves as a vital resource for engineers and designers in ensuring the integrity and safety of piping systems. This section of the code delineates specific requirements and constraints that must be adhered to when incorporating miter bends into piping designs.

ASME B31.3 offers two distinct methods for determining the maximum allowable pressure for miter bends: the single miter method and the multi-miter bend method, the latter accommodating configurations with 2 to 5 miter cuts. Each method accounts for various factors such as material properties, geometrical considerations, and operational parameters to ascertain the safe operating limits of the miter bend within the given system.

To streamline the design process and facilitate compliance with ASME standards, specialized software programs have been developed to assist engineers in calculating pressure ratings, material properties, and ensuring adherence to the pertinent regulations. These programs typically feature comprehensive databases of common materials properties, factor tables, and algorithms that perform compliance checks against the relevant provisions of the ASME B31.3 code.

By leveraging such software tools, engineers can expedite the design process, mitigate risks, and optimize the performance of piping systems while ensuring compliance with industry standards and regulations. This integration of technology not only enhances efficiency but also contributes to the overall safety and reliability of critical infrastructure projects.

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.