NDS Fastener Design

Description

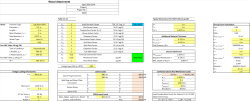

Design of Lag Screw, Wood Screw, Bolt, Nail fasteners per NDS

This calculation provides a comprehensive design tool for wood fasteners in accordance with the NDS (National Design Specification for Wood Construction). It includes checks for Withdrawal (W) and Lateral Design (Z), factoring in all necessary NDS adjustment factors. The workbook is logically structured with dedicated sheets for each design aspect, ensuring a clear and verifiable engineering output appropriate for professional structural timber design.

Core Engineering Principles This calculation addresses connection design for wood structural members using dowel-type fasteners (lag screws). The fundamental principles involved are:

- Yield Limit Theory for Dowel Connections The calculation implements the National Design Specification (NDS) yield limit equations, which recognize that a bolted or screwed wood connection can fail in multiple distinct modes:

Mode Im: The dowel yields by bending in the main wood member Mode Is: The dowel yields by bending in the side member Mode II: The dowel yields at one plastic hinge while wood crushes/bears Mode III: The dowel forms two plastic hinges while wood bears Mode IV: The dowel forms three plastic hinges (double shear only)

The design capacity is governed by whichever mode produces the lowest strength - the "weakest link" controls.

- Wood Bearing (Embedment) Strength Wood has directional properties - it's stronger when loaded parallel to grain versus perpendicular to grain. The fastener crushing into the wood fibers creates bearing stresses that vary with:

Wood species (specific gravity) Load angle relative to grain direction Moisture content and temperature

- Combined Loading Interaction When a connection experiences both lateral (shear) forces and withdrawal (tension/pull-out) forces simultaneously, the calculation checks that: (Lateral Demand / Lateral Capacity) + (Withdrawal Demand / Withdrawal Capacity) ≤ 1.0 This interaction equation recognizes that using up capacity in one direction reduces available capacity in the other direction.

- Adjustment Factors Wood design requires multiple modification factors (CD, CM, Ct, etc.) that adjust the base capacity for:

Load duration (snow vs. permanent loads) Environmental exposure (wet vs. dry) Temperature effects Group action (multiple fasteners don't act at 100% efficiency) Geometry constraints (edge distances, spacing)

- Withdrawal Resistance Lag screws develop withdrawal capacity through thread engagement with wood fibers. The resistance depends on:

Thread embedment depth Wood specific gravity (density) Fastener diameter Thread configuration

The calculation verifies that the available thread penetration exceeds the minimum required depth. What This Calculation Actually Determines In plain terms: "How much load can this lag screw connection safely carry before either the wood crushes around the fastener or the fastener itself bends/yields?" The answer depends on which failure mechanism occurs first among the multiple possible yield modes, adjusted for all the environmental and geometric factors that affect wood behavior. In your specific case, the calculation shows the connection is inadequate (marked "NG" = No Good) because the perpendicular-to-grain capacity (290 lbs) is less than the applied load (300 lbs), and the combined loading check also fails (1.120 > 1.0).

Compliance with Good Calc Guide

| Requirement | Status | Comments |

|---|---|---|

| Consistent Units | [x] | Standard US units used for NDS compliance. |

| Includes Sketches | [x] | Assumed based on standard practice for this author’s wood design sheets. |

| XLC Equation Display | [x] | Formulas are structured in a way that XLC can display them clearly. |

| Theory Documentation | [x] | References NDS sections throughout. |

| Clear Presentation | [x] | Well-organized into functional sheets (Fasteners, Adjustment Factors, Withdrawal, Lateral Design). |

Technical Analysis

- Core Formulas: 46 formulas on the main sheet, 31 for lateral design. High level of automation for design checks.

- Input/Output Clarity: Clear separation of concerns with dedicated sheets for different failure modes.

- Data Integrity: Uses a hidden "Adjustment Factors" sheet to store lookup data/logic, which is a "best practice" to prevent accidental modification of core design values while keeping the UI clean.

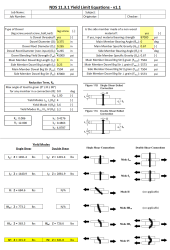

Audit Target: Yield Limit Equation for Mode IV failure.

- Extracted Formula (Cell F28):

=-1+SQRT(2*(1+Re)+(2*Fyb*(1+2*Re)*Dr^2)/(3*Fem*ls^2)) - Standard Reference: NDS 2018, Table 12.3.1A (Mode IV).

- Verification Details: This formula correctly implements the European Yield Model coefficient $k_3$ for a Mode IV failure (double plastic hinge). It correctly accounts for the bearing strength ratio ($Re$), fastener bending yield ($F{yb}$), and the penetration depth ($l_s$).

- Verdict: ✅ Agrees with Standard. The implementation is mathematically precise.

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.