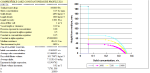

Compressible Cake Constant Rate Filtration

Description

Simulation of the batch sedimentation of compressible compacts is also possible using an

appropriately coded computer spreadsheet. The governing equation for this type of sedimentation

is a non-linear parabolic partial differential equation that must be solved by a numerical technique

such as Finite Difference. This has been achieved using a spreadsheet, and examples of how to

use the simulation and the results are provided and compared with data taken during batch

sedimentation of compressible compacts whilst monitoring the local concentration within the

vessel using an electrical conductance technique.

Calculation Reference

Fluid mechanics

Filtration

Chemical Plant Design

In the filtration process, a compressible cake forms when particles in the slurry being filtered accumulate on the filter medium, resulting in a cake with a variable resistance to flow. The resistance of the cake increases as it compresses under the applied pressure. Constant rate filtration is a mode of filtration where the rate of filtrate flow remains constant throughout the process.

For compressible cake constant rate filtration, the rate of filtrate flow (V) is maintained constant, and the pressure drop (?P) across the filter medium and the cake increases over time. The rate of filtrate flow can be described by the modified form of Darcy's law for compressible cakes:

V = (A * ?P) / (? * (R_m + ? * S))

where:

- V = volumetric flow rate of filtrate (m³/s)

- A = filtration area (m²)

- ?P = pressure drop across the filter medium and cake (Pa)

- ? = dynamic viscosity of the filtrate (Pa·s)

- R_m = resistance of the filter medium (m-1)

- ? = specific cake resistance (m/kg), which varies with the applied pressure for compressible cakes

- S = mass of solids per unit area (kg/m²)

In constant rate filtration, V is constant, and the pressure drop (?P) increases with time as the cake compresses. Therefore, the specific cake resistance (?) also changes as a function of pressure or time. A common empirical model used to describe the relationship between ? and ?P is:

? = ?0 * (?P)^(n - 1)

where:

- ?0 = specific cake resistance at a reference pressure (m/kg)

- n = compressibility index, which indicates the extent to which the cake compresses under pressure (dimensionless)

The compressibility index (n) typically ranges from 1 for incompressible cakes to greater than 1 for compressible cakes. For constant rate filtration with a compressible cake, the relationship between filtrate volume (V_f), filtration time (t), and the other process parameters needs to be determined experimentally or using numerical methods. This often involves performing laboratory-scale filtration tests and analyzing the data to determine the appropriate model parameters.

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.