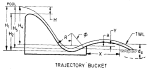

HYDRAULIC DESIGN OF TRAJECTORY BUCKET TYPE ENERGY DISSIPATOR

Description

HYDRAULIC DESIGN OF TRAJECTORY BUCKET TYPE ENERGY DISSIPATOR

The design is based on IS 7365:1985.

1. Salient levels:

2. Bucket invert elevation:

3. Calculation for approach velocity:

4. Calculation for bucket radius:

5. Angle of lip:

6. Trajectory bucket pressure:

7. Calculation for lip level and Tangent point:

8. Slope of the lip:

9. Trajectory length:

10. Depth of scour:

Calculation Reference

Flood

Energy Dissipator

IS 7365

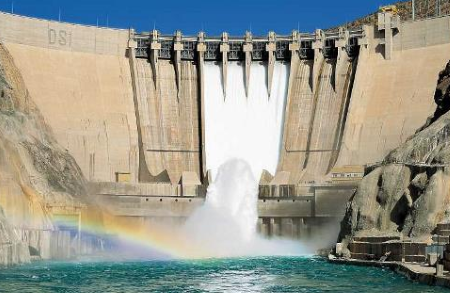

The hydraulic design of a trajectory bucket type energy dissipator is an important consideration in the construction of hydraulic structures, such as spillways and channels. The design is based on the Indian Standard IS 7365:1985, which provides guidelines for the design and construction of hydraulic structures.

The trajectory bucket type energy dissipator is a hydraulic structure that dissipates the energy of a high-velocity fluid flow by deflecting it through a series of buckets or baffle plates. The design of the dissipator involves calculating the dimensions and geometry of the buckets and plates to ensure that the flow is properly deflected and the energy is dissipated without causing excessive turbulence or erosion.

The hydraulic design of a trajectory bucket type energy dissipator involves the following steps:

-

Determination of the design flow rate and head, based on the specific project requirements and site conditions.

-

Calculation of the required energy dissipation capacity of the dissipator, based on the flow rate and head.

-

Selection of the appropriate bucket or plate geometry, based on the flow rate, head, and available space.

-

Calculation of the bucket or plate dimensions and spacing, based on the required energy dissipation capacity and the selected geometry.

-

Evaluation of the hydraulic performance of the dissipator using physical models or numerical simulations, to ensure that the flow is properly deflected and the energy is dissipated without causing excessive turbulence or erosion.

-

Design of the inlet and outlet structures of the dissipator, to ensure smooth and efficient flow transitions.

The design of a trajectory bucket type energy dissipator requires expertise in hydraulic engineering and fluid mechanics. The Indian Standard IS 7365:1985 provides guidance and procedures for carrying out the design, ensuring that the dissipator is safe, efficient, and effective in dissipating the energy of high-velocity fluid flows.

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.