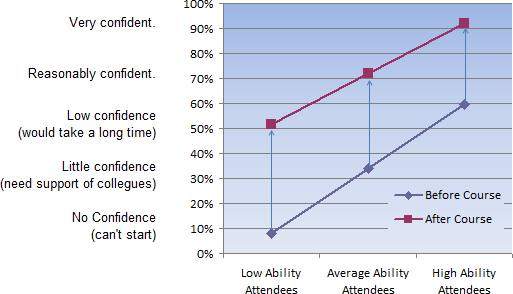

Engineering training - “I run a team of engineers and whilst there are plenty of soft options for training expounding the latest management techniques there is precious little to develop the engineering skills of my team”. This is a familiar story we hear from clients of our training services. Our Excel design guides provide interactive charts to demonstrate the underlying science they make a fast track for learning and become invaluable resources for later use. We demonstrate the effectiveness of training by surveying confidence levels before and after the course. We split the class into low ability, average ability and high ability attendees and all levels show a marked increase in confidence levels.

Low ability attendees start without any hope of starting a problem but show the greatest increase in confidence. Average ability attendees start being able to tackle problems only with the support of colleagues but leave tackling problems on their own. Even high ability attendees start with a reasonable level of confidence but leave being able to solve problems much more confdence and speed thanks to their new spreadsheet guides.

|

Weld Strength (½ day)

Fracture Surfaces (½ day)

Bolts (½ day)

Safe Life Fatigue (½ day)

Dynamics (½ day)

|

Fatigue of Welds (½ day)

Links and Mechanisms (½ day)

Beams and Frames (½ day)

Miscellaneous Topics (½ day)

Excel Skills for Engineers Course Customisation: Customise training for railway vehicles, construction equipment, oil and gas plant, cranes, mining equipment and theme parks. Course Duration: Select your own training modulues (typically 2 to 5 days). Course size: 5 to 50 attendees. Course Location: In house training delivered at any location. Contact John Doyle to discuss your requirments. |

Apologies to trial users in December

Many trial users could not install their XLC trial in December this was due to an oversight on our part. Anyone can subscribe to our trial plan as many times as they wish so please feel free to download XLC again to find out just what you are missing out on.

Follow us on Twitter or LinkedIn

Follow us on twitter or join our Linked In Group to keep up to date with site developments as they happen.

Site Improvements

Those of you returning to the site will notice quite a few improvements including:

• The addition of social network referral buttons allows you to recommend a page to your friends on Twitter, LinkedIn, Facebook and Google+. We would be grateful if you would use these.

• The site has been optimised for viewing on mobile devices.

Repository News

Uploads seem a little sluggish in January. Remember we offer free subscriptions for any contributions.

| 2012 Jan. 12 | |

| 2012 Jan. 09 | |

| 2012 Jan. 05 |