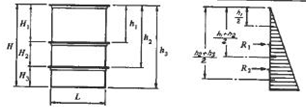

Rectangular Tank Design with Horizontal Stiffening

Description

This workbook is for the design of rectangular atmosphere tanks with horizontal stiffening. The calculations are based on those found in the "Pressure Vessel Handbook" and "Roark's Formulas for Stress and Strain"

Calculation Reference

Pressure Vessel Handbook

Roark's Formulas For Stress and Strain

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.

Comments: 5

×

namasral

11 years ago

Do email me, maybe I can help, fwd me the all info required..namasral@gmail.com

14 years ago

Hello there, I would like to know, if there is any standard to design the Rectangular tanks at atmospheric pressure accepted by national bodies or industries. I have been trying to locate such a standard but it seems of no use. I have instead found some stuff, just google wis-4-25-01 pdf and probably it might give some guidelines. the problem i am facing is I want to make a Fire water rectangular tank 10m x 5m x 2m although i can take help of roarks equations for stiffening, i will have to use some standard to define my design. please suggest me if any of you have any idea.

Thanks,

J Kamisetty

Thanks,

J Kamisetty

15 years ago

Anybody know why Megyesy uses 0.3 in the thickness equation? I have the eleventh edition of book, maybe newer editions explain this?

16 years ago

Hi Jestanks,

The formula that I used for the reactions on the stiffeners is directly out of the 8th edition of the "Pressure Vessel Handbook" by Megyesy (the scanned image at the top of the spreadsheet), not that that necesarily gaurantees that it is correct, I have found some errors in it myself. My assumption as to why the reactions on the stiffeners is scaled to 70% is that Megyesy is giving some credit to the plate itself in resisting the horizontal force.

I am always open to any and all sugestions on how to better engineer things, especially from those with more experience than myself. So please by all means share any thoughts and experiences with me that you'd like.

Thank You very much for your comments and I look forward to more.

David

The formula that I used for the reactions on the stiffeners is directly out of the 8th edition of the "Pressure Vessel Handbook" by Megyesy (the scanned image at the top of the spreadsheet), not that that necesarily gaurantees that it is correct, I have found some errors in it myself. My assumption as to why the reactions on the stiffeners is scaled to 70% is that Megyesy is giving some credit to the plate itself in resisting the horizontal force.

I am always open to any and all sugestions on how to better engineer things, especially from those with more experience than myself. So please by all means share any thoughts and experiences with me that you'd like.

Thank You very much for your comments and I look forward to more.

David

16 years ago

I was excited to see your spreadsheet and I haven’t had a chance to go completely through it yet, but I plugged in some numbers to check it out. I applaud your work to ease the design process of designing rectangular tanks with horizontal stiffeners. There isn’t a lot of info out there on designing rectangular tanks, and some of it has questionable elements. Being an older engineer, I have been doing this type of design work for some time and have my own approach (based mostly on Roark’s equations) which isn’t too far off yours. In your spreadsheet, I question the values of the Reactions on each of the stiffeners as calculated. The sum of all the reactions including the top edge should equal the total load on the vertical wall per the same length unit. In my experience the lowest stiffener (not the bottom edge) usually has the greatest load. I use a standard engineering method for figuring the reactions that isn’t shown in texts on the rectangular subject. I do my calcs by hand which is time consuming since it is a back and forth game to get the best panel thickness verses width and height. Also tweaking the heights of multiple stiffeners to minimize the loads on them helps balance the design. I appreciate your efforts in this cause and would be open to sharing my thoughts and experience if you have any interest. Sincerely, Jestanks