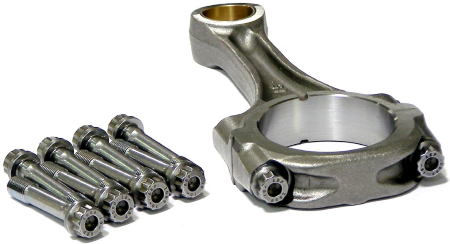

Connecting Rod Bolts Calculation with VDI 2230 standards

Description

I have calculated the Connecting rod bolt analysis with VDI 2230 standards.I still think I have made so many mistakes.Please help me update this.I will add graphical results later.

The calculation of connecting rod bolts using the VDI 2230 standard involves following specific guidelines and formulas to ensure the safe and reliable design of the bolted joint. VDI 2230 is a German standard that provides comprehensive guidelines for the calculation and design of bolted joints, including connecting rod bolts.

Here is a general overview of the process involved in the calculation, based on the VDI 2230 standard:

-

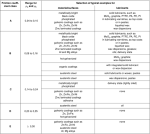

Determine Load Introduction: Identify the maximum inertia force and bearing load on each bolt. This involves considering the application and type of load that the connecting rod will experience.

-

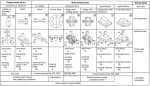

Define Clamping and Joint Type: Specify the type of clamping and the type of bolted joint. This includes considering factors such as the type of tightening method, the type of bolt and thread, and any special requirements for the specific application.

-

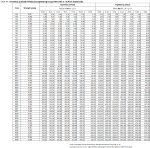

Calculate Minimum Clamp Load: Determine the total minimum clamp load required for the connecting rod joint. This involves considering factors such as resilience, load factors, and any additional external loads applied to the joint.

-

Evaluate Preload Losses: Consider any preload losses that may occur due to embedding effects or temperature changes. This helps ensure that the desired preload is maintained in the bolted joint.

-

Determine Assembly Stresses: Evaluate the stresses that occur during assembly, considering the utilization factor of yield point stress during tightening. This helps ensure that the assembly stresses are within the allowable limits for the selected bolt.

-

Assess Working Stresses and Yield Point Factor of Safety: Calculate the comparative stresses in the working state, taking into account the yield point factor of safety. This helps determine if the joint preload is sufficient to maintain the required clamp load, even in scenarios where the yield point of the bolt is exceeded.

-

Consider Alternating Stresses and Fatigue Factor of Safety: Evaluate the alternating stresses and determine the factor of safety against fatigue failure. This is important to ensure that the bolts can withstand the cyclic loading without experiencing fatigue failure.

-

Evaluate Surface Pressure and Factor of Safety: Calculate the actual surface pressure on the clamped parts and compare it to the limiting surface pressure. This helps ensure that the surface pressure is within acceptable limits and provides a factor of safety against surface pressure failure.

-

Determine Minimum Length of Thread Engagement: Assess the critical thread and determine the minimum length of engagement required between the bolt and nut or internal threaded component. This ensures proper engagement and avoids thread stripping or failure.

-

Assess Residual Clamp Load, Slipping, and Shearing: Determine the minimum residual clamp load in the bolted joint and evaluate the factors of safety against slipping and shearing of the bolt. This helps ensure that the joint remains secure and avoids any potential failure modes.

-

Calculate Tightening Torque: Determine the tightening torque that can be applied to the bolted joint. This ensures that the bolt is properly tightened to achieve the desired preload and clamp load.

It is important to note that the VDI 2230 standard provides detailed formulas, tables, and guidelines for each step of the calculation process. Following the standard's recommendations and using the appropriate formulas and tables will ensure accurate and reliable results.

Calculation ReferenceBolted Joint Analysis

VDI 2230

Structural Assessment of Bolted Joints

Calculation Preview

Full download access to any calculation is available to users with a paid or awarded subscription (XLC Pro).

Subscriptions are free to contributors to the site, alternatively they can be purchased.

Click here for information on subscriptions.