|

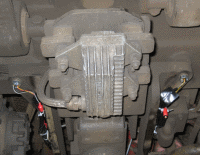

Possibly the most devastating engineering failure of 2009 occurred near Sayanogorsk in south central Russia. The photo below shows Russian Prime Minister Vladimir Putin visiting the accident site and is well documented on YouTube and the Boston Globe. A catastrophic accident took place in the turbine and transformer rooms of the hydroelectric plant of the Sayano-Shushenskaya dam causing a transformer explosion and extensive damage to all ten turbines. 74 workers are known to have lost their lives in the accident. The root cause of the incident is the failure of that most basic of engineering components, the 'simple' bolt.

Every engineer experiences some difficulties with bolts at some point in his career. So what typically goes wrong and what can we do to prevent bolt problems? Follow our bolt failure checklist and find calculations to help you.

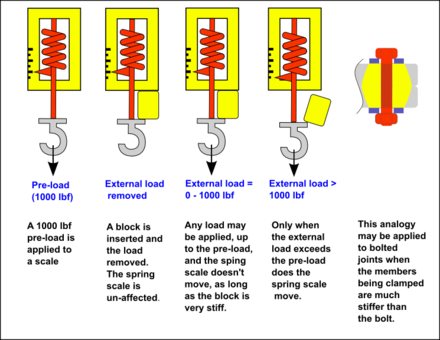

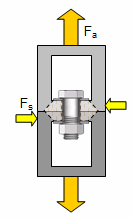

- Insufficient Clamp force? - Usually by applying a measured torque load to the nut bolted joints are tightened to achieve a specific clamp load. Even under the most extreme applied loads, the clamping force must prevent joint movement between clamped parts. Movement includes both opening of the joint to form gaps and slipping. Loads applied to the joint may be axial forces (in the direction of the bolt axis) and/or shear forces (perpendicular to the bolt axis). If slippage occurs then the joint may fail by the bolt loosening. If a gap in the joint opens then a bolt failure by fatigue is more likely to occur. Typically bolt fatigue failures occur because of insufficient preload rather than poor fatigue strength of the bolt. Improving the method of tightening can reduce the scatter in bolt preload and help guarantee the minimum required clamping force.

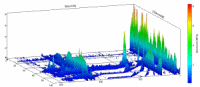

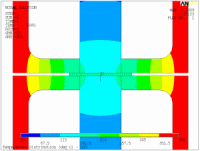

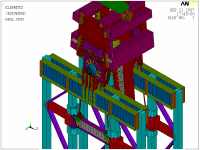

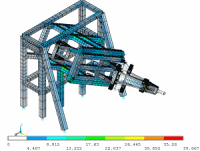

- Excessive Applied Force? - If a very high axial force is applied to a joint the bolt may be loaded beyond its yield strength. If a direct tensile failure does not occur immediately then plastic deformation will result in preload loss and subsequent failure by loosening or bolt fatigue. Knowledge of the applied loads may require calculations, finite element analysis or strain gauge testing.

- Joint Relaxation? - Joints which loose bolt preload in service are said to suffer from joint relaxation. There may be a number of reasons for joint relaxation. Embedding occurs when high bearing pressure under the nut face exceeds the compressive yield strength of the joint material. The resulting plastic deformation gives rise to loss of bolt preload. Differential thermal expansion in joints comprising dissimilar materials can lead to loss of bolt preload and prolonged exposure to high temperatures will increases the risk bolt creep.

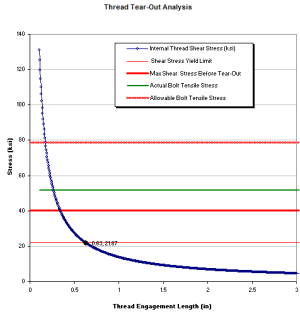

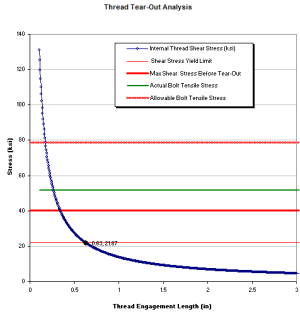

- Thread Stripping? - Thread stripping is a shear failure of an internal or external thread. Thread stripping tends to be gradual in nature and it may go unnoticed at the time of assembly. This may have disastrous consequences on product reliability.

Bolt Investigation Techniques

Bolted joints are one of the most common elements in construction and machine design yet they are the root cause of half of the failures investigations undertaken by MoreVision. All bolt problems can be solved by understanding the mechanics of the bolted joint, the loads to which it is subjected and the environment to which it is exposed. The table below shows common techniques that we use to solve bolt design problems.

| |

Analysis/Simulation |

Test/Verification |

| Bolted Joint Assessment |

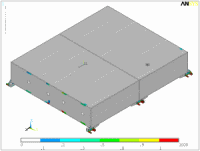

Joint modelling.

Dissimilar materials.

Thread mechanics.

Control of tightening.

Relaxation, embedding. |

Lab testing of bolted joint assemblies.

Junkers (vibration) testing.

Onsite tightening tests.

|

| Bolt Applied Forces |

Finite element analysis.

Vibration analysis.

Thermal modelling. |

In service testing.

Signal processing and analysis of results. |

Our Bolt Investigation Team

John Doyle is a UK chartered mechanical engineer consulting in the fields of simulation, finite element analysis and engineering calculations. John’s website www.morevision.co.uk shows many bolt failure case studies. John also runs the engineering website www.ExcelCalcs.com which includes many bolt/thread calculations. His analysis and testing services have been used for railway vehicles, construction equipment, oil and gas plant, cranes and mechanical items for theme parks. |

MoreVision enlist the support of Bill Eccles, also UK chartered mechanical engineer who researches and specialises in bolts. Bill’s aptly named www.boltscience.com website covers all variety of technical matters regarding bolts. Bill wrote and developed BOLTCALC which is highly recommended for the analysis of bolted joints. Rest assured that Bill is arguably the world’s most eminent authority on bolts. It is unlikely that you have a problem that Bill has not already encountered some way in his career. |

The ‘simple bolted joint’ can be anything but simple. MoreVision and BoltScience offer a unique skill set to solve your bolting problems. Please contact John Doyle if you require our assistance with your own bolt problems.

Our Consultancy Services

Bolted Joint Design Check

– Email all the joint details (bolt specification, clamped materials, tightening procedure, applied axial and shear forces, temperature) and using our databases and analysis tools we’ll produce a report which identifies any area of risk. Maybe you would just like an independent review of your bolting procedures?

Bolt Loading Assessment

– Not entirely sure what loads your joint will be subjected to? If classical calculations are not enough we use finite element analysis to calculate the loads to which a bolt is subjected. Analysis methods available to us are inertia load assessment, dynamic load assessment, random vibration assessment, thermal assessment and fatigue assessment.

Bolt Lab Test

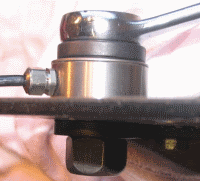

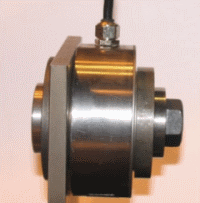

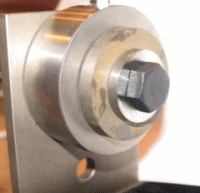

– Send us your bolt and in addition to the bolted joint design check report we’ll measure the torque tension relationship for your joint using load cells.

Bolt Value Engineering

– We help clients replace expensive custom made bolts with cheaper alternatives with no loss in structural performance. Our last value engineering exercise save one of our clients over 1 million dollars.

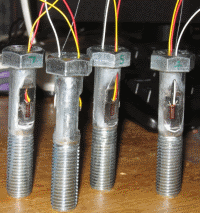

On Site Bolt Testing

– If your joint is too big to send to us we’ll come to you. It may be appropriate to use pre-calibrated strain gauged bolts which we can specially prepare for you. Our last test involved monitoring bolts on a railway vehicle. Our measurements were linked to Google Earth via a GPS to that we could identify parts of the railway infrastructure which gave rise to high bolt loads.

Bolt Failure Investigations

– Ask our team for an independent failure investigation. Our combined bolting experience and analysis tools and skills places you in the strongest position to investigate the root cause of bolt failure. Given the nature of bolt failures this service is offered on an independent and confidential basis.

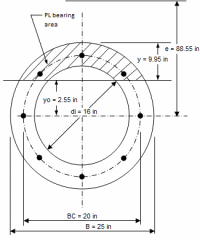

This is a pretty simple bolt calculation from first principles. For a given bolt size it looks up the characteristics of a bolt from a 'Bolt Lookup Table'. A bolt preload (or clamping load) is...

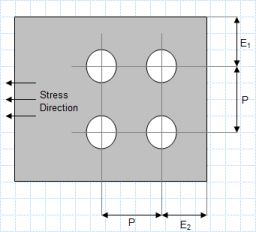

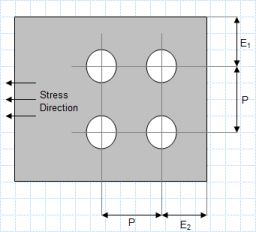

Calculate the minimum and maximum fastener spacing, end and edge distan...

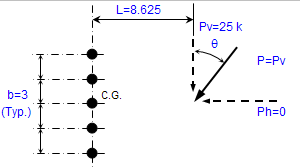

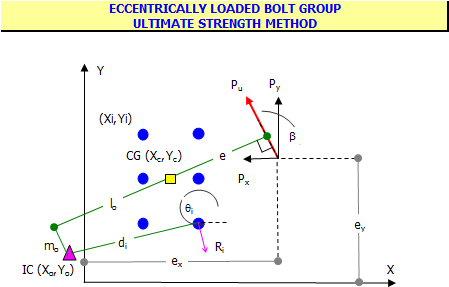

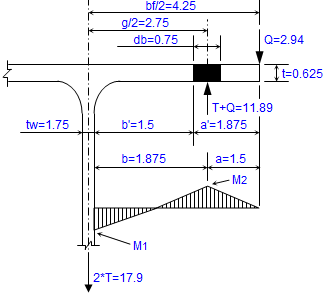

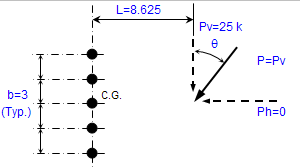

"BOLTGRP.xls" is a MS-Excel spreadsheet workbook for analyzing bolt groups... "BOLTGRP.xls" is a MS-Excel spreadsheet workbook for analyzing bolt groups...

-

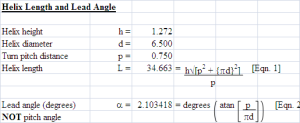

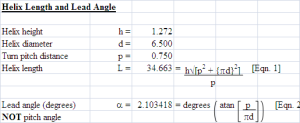

Helix Length and Lead Angle.xls Helix Length and Lead Angle.xls

A simple calculation to find the length and lead angle of a helix. Calculation Reference Machinery's Handbook

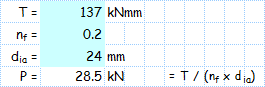

Optimize bolt tapping depth, tension and tear out strengt...

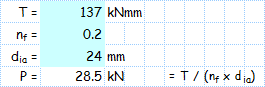

Simple calculation of the tension in a bolt from the torque imposed or visa versa.

|