Bolts and Threads

0 ContainersFiles in Bolts and Threads

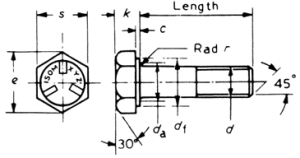

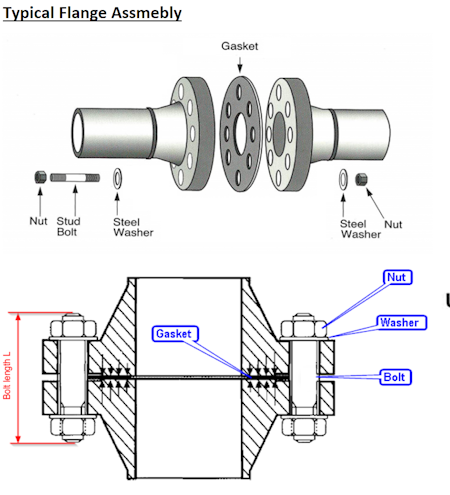

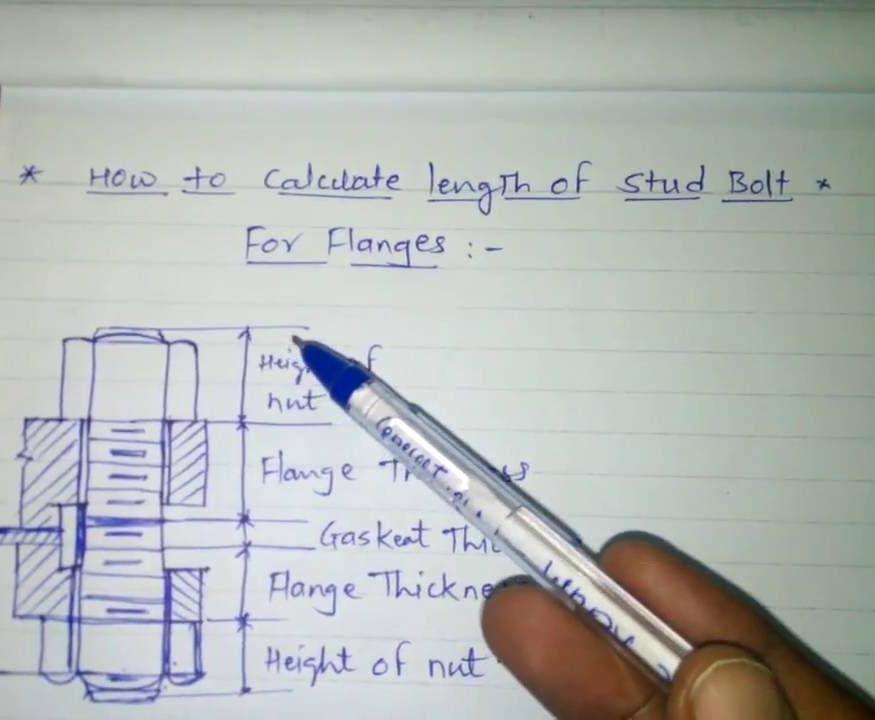

Bolt length calculator

Given the clamping thickness, the bolt length would be calculated

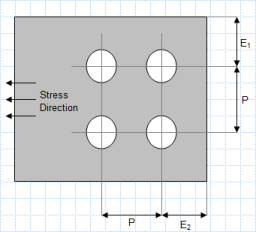

Bolt spacing and edge distances.xls

The minimum and maximum fastener spacing, end distances, and edge distances for steel plates are t...

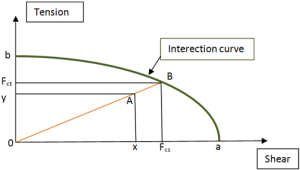

Bolt Stress MIL-HDBK-5

Calculates the allowable pre-load after a user input shear load or the allowable shear load after a user input pre-load for coa...

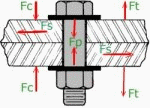

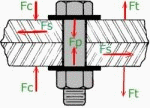

BoltedJoint.xls

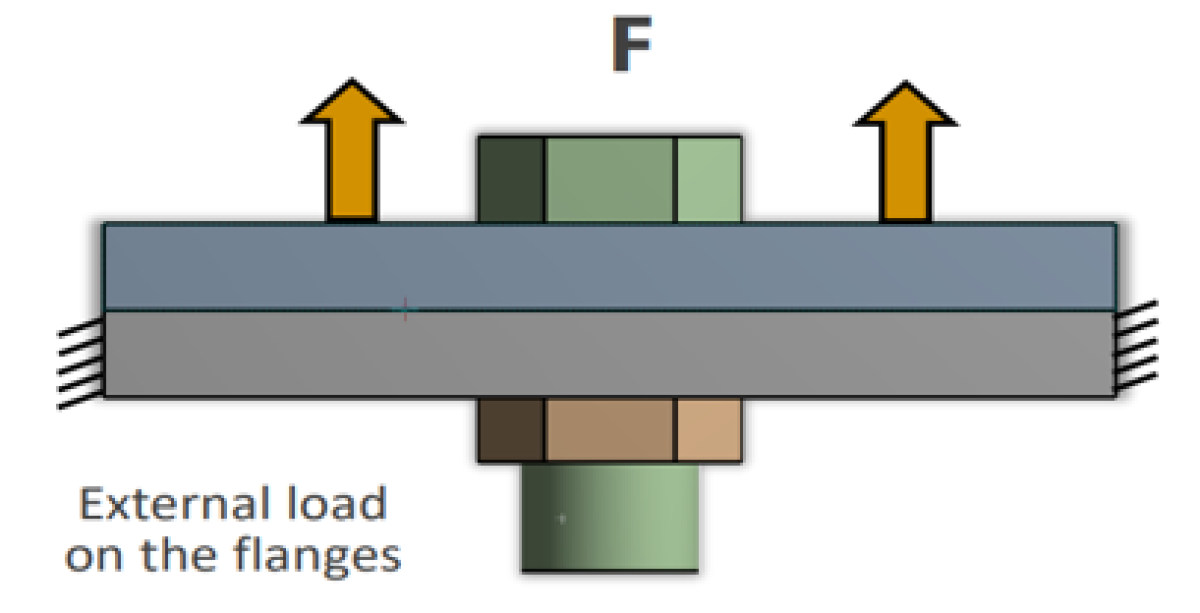

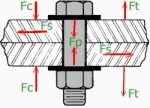

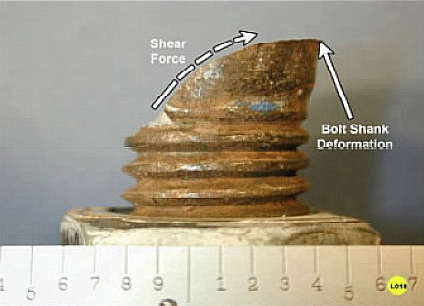

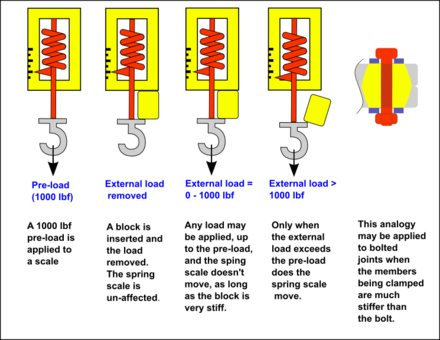

To determine the force distribution in a preloaded bolted joint, you can follow these steps:

Understand the Joint Configuration...

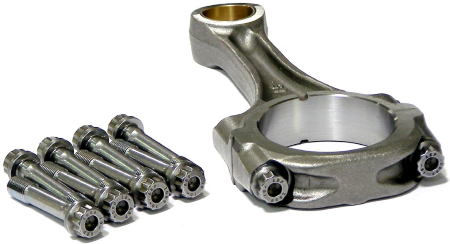

Connecting Rod Bolts Calculation with VDI 2230 standards

I have calculated the Connecting rod bolt analysis with VDI 2230 standards.I still think I have made so many mistakes.Ple...

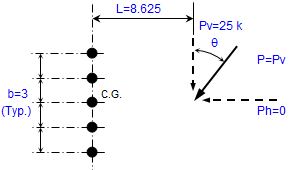

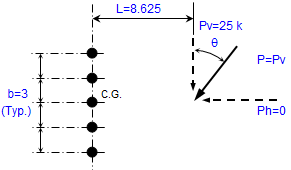

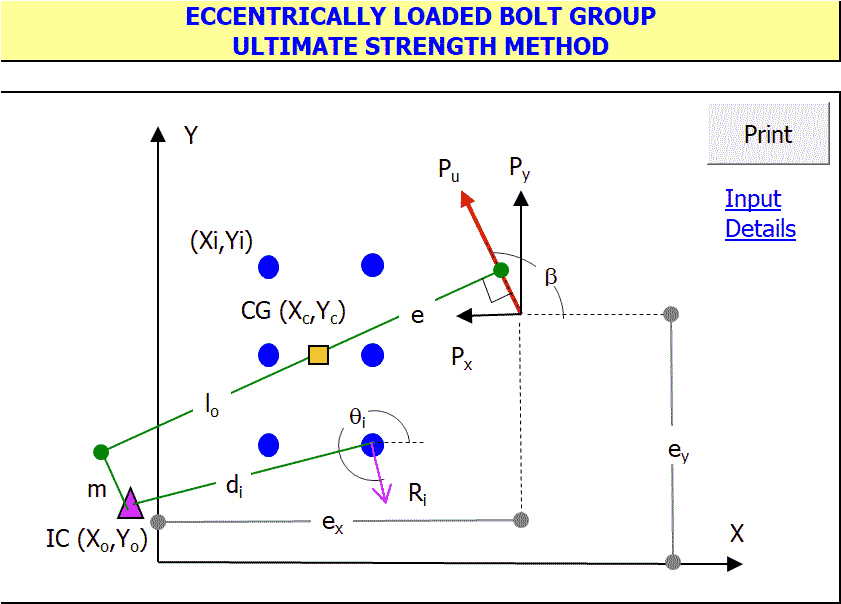

Eccentric Loaded Bolted Joint

Enter bolt locations, applied load and location of load. Calculates bolt shear, tension, etc. I use this all the time at work and it ma...

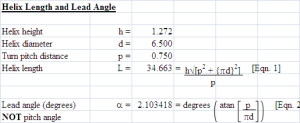

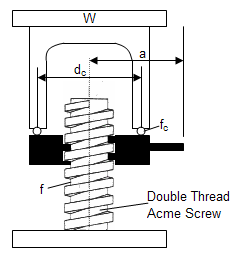

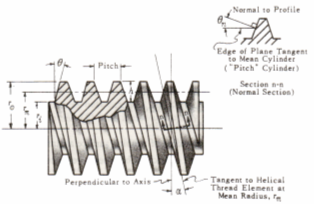

Power screw calculations.xls

KNOWN: A double thread Acme screw and a thrust collar, each with known diameter and running friction coefficient, are used to raise a speci...

Power Screw.xls

Purpose of calculation: For an applied load on a screw thread calculate the axial thrust of a nut. Calculate bolt pretension from screw parameter...

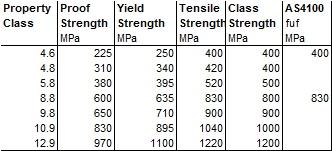

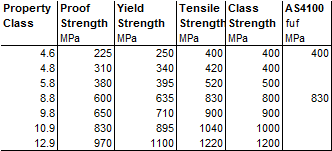

Quick and Dirty Bolt Sizing Calculation.xls

https://www.youtube.com/watch?v=x5G5xPAt5To

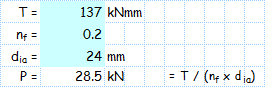

The following values are required as inputs to the calculation:

- BOLT GRADE - Enter the two num...

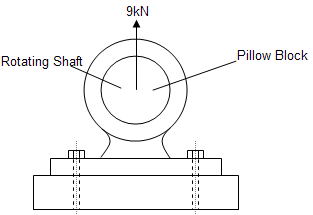

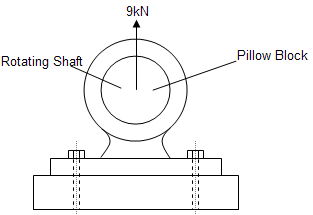

Steel Roller Structural Analysis

AMERICAN INSTITUTE OF STEEL CONSTRUCTION, INC. (AISC)

Specification for Structural Steel Buildings

Allowable Stress Design and Plastic Design

...