Fatigue

0 ContainersFiles in Fatigue

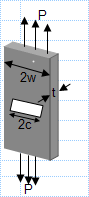

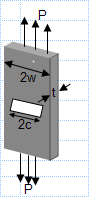

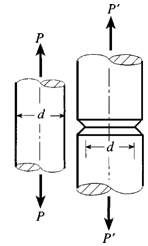

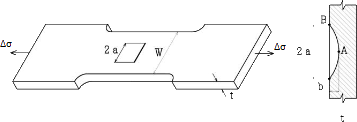

Assessment of Flaw in Centre of a Plate in Tension

Description Flaw Assessment OverviewObjective of the Calculation

Employing fracture mechanics principles, this calculation adheres ...

Fast Fracture - Plate with an Edge Crack.xls

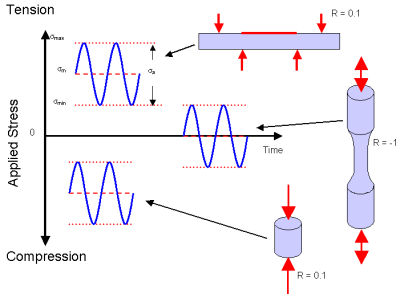

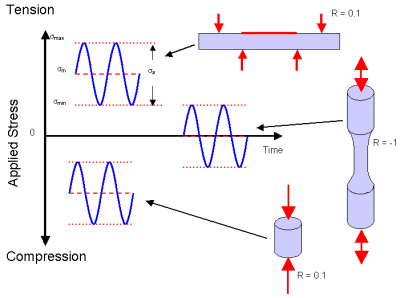

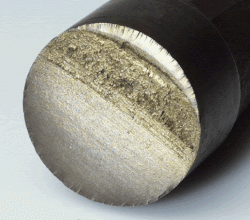

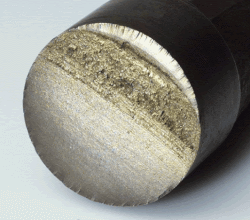

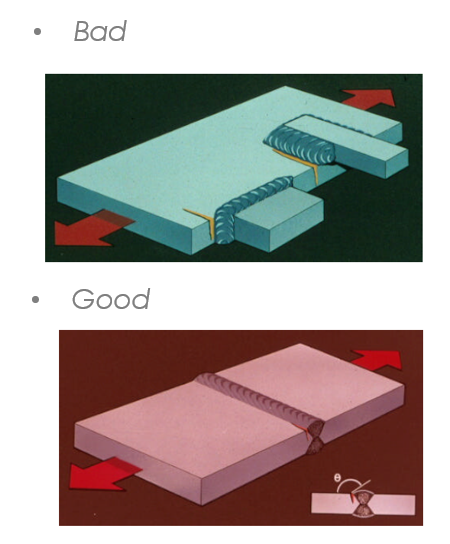

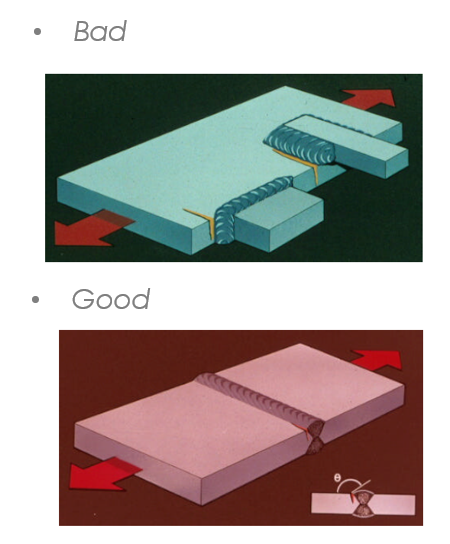

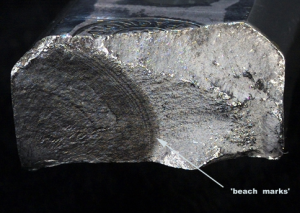

The darker area characterised by beach marks shows how the crack has grown from repeated loading. This crack growth phenomenon is...

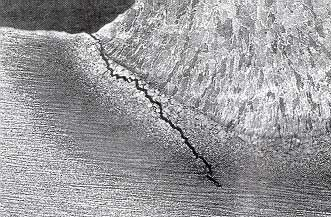

Fatigue

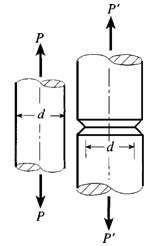

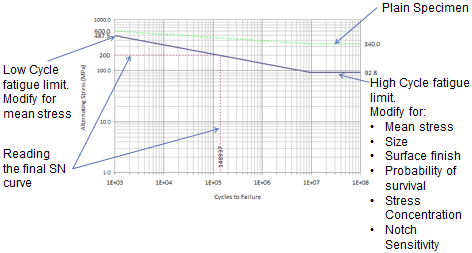

Both SN curve and Goodman diagram are commonly used approaches to study fatigue in engineering and material science. SN curve is a g...

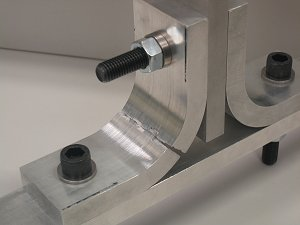

Fatigue Damage in Aluminium Welds.xls

Calculate fatigue damage in an aluminium weld subjected to constant amplitude loading and variable amplitude loading accordi...

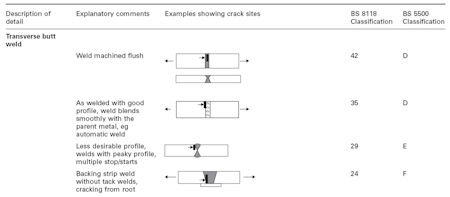

Fatigue Damage in Steel Welds.xls

Calculate fatigue damage in a steel weld subjected to constant amplitude loading and variable amplitude loading. Based on methods described i...

Juvinall's Fatigue Life Method.xls

https://www.youtube.com/watch?v=o-6V_JoRX1g

Juvinall's Fatigue Life Method (Excel Tool) Description Calculat...