Courses currently being scheduled:

- Railway Vehicle Structural Integrity (1 to 5 days)

- Fatigue of Welded Structures (2 day)

We endeavour to our material as accessible as possible from the website but the best way to learn is to attend one of our training days where the ExcelCalcs creator, John Doyle, will present the material in the context of real life engineering case studies. All courses are modular and are easily customised for any organisation. We offer competitive packages for corporate clients delivering our on-site training anywhere in the world. Attendees can expect a 23% productivity boost by taking the course. An indicative price is $300USD per user per day plus expenses for a group of 12 people and can be presented anywhere in the world. Please contact us to discuss your requirements or base it on one of our previous courses:

- ExcelCalcs Daytrip (1 day)

- Fatigue of Welded Structures (2 days)

- Structural Design (2 days)

- Mathematical Modelling for Engineers (2 days)

- Railway Vehicle Structural Integrity (1 to 5 days)

- Design of Railway Vehicles (5 days)

- Design of Construction Equipment (5 days)

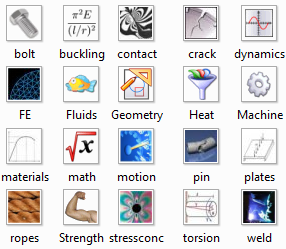

COURSE MODULES: Our engineering courses can be custom built to your company's needs by

selecting individual modules (see list below). All courses are developed

and presented by practising engineers so courses have a practical bias

rather than an academics bias. Uniquely ExcelCalcs training courses uses

XLC spreadsheets which make powerful training resources and tools for

use long after the course is complete. Each attendee is given a web

access key to unlock unique course material. The courses include

presentations, XLC spreadsheets, videos, tutorials, quizzes and

practical workshops. They usually conclude with a short examination and a

certificate of competence for attendees. Participants will continue to

be supported after training via the course forum. Please email for a quotation specifying your content preferences from:

COURSE MODULES: Our engineering courses can be custom built to your company's needs by

selecting individual modules (see list below). All courses are developed

and presented by practising engineers so courses have a practical bias

rather than an academics bias. Uniquely ExcelCalcs training courses uses

XLC spreadsheets which make powerful training resources and tools for

use long after the course is complete. Each attendee is given a web

access key to unlock unique course material. The courses include

presentations, XLC spreadsheets, videos, tutorials, quizzes and

practical workshops. They usually conclude with a short examination and a

certificate of competence for attendees. Participants will continue to

be supported after training via the course forum. Please email for a quotation specifying your content preferences from:

●XLC and ExcelCalcs

●XLC and ExcelCalcs

●Bolting and mechanical fasteners

●Welding and joining materials

●Static strength and fatigue design

●Pins and lugs

●Failure criteria and biaxial stress assessment

●Material properties and material selection

●Steel and aluminium design

●Fatigue of welded structures

●Fracture mechanics

●Strain gauge or calculate?

●Failure Investigations

●Design for impact loads and dynamic effects

COURSE LEADER: John Doyle BSc(eng)., Ceng., MIMechE., ACGI was born in

1965 and is a graduate of London’s Imperial College with some 25 years

of experience in solving engineering problems. After graduating he

joined Rolls Royce where he attained chartered status with the Institute

of Mechanical Engineers. Having risen to the position of Chief

Mechanical Engineer with Bombardier Transportation he started his own

engineering consultancy in 1995 called MoreVision. It specialises in

engineering analyses applied to railway vehicles, construction

equipment, oil and gas plant, cranes and mechanical items for theme

parks. His client list includes Shell, Bombardier, Siemens, Volvo and

Disney. He won a UK Government SMART competition for software innovation

and his website attracts over 18,000 unique visitors every month.

COURSE LEADER: John Doyle BSc(eng)., Ceng., MIMechE., ACGI was born in

1965 and is a graduate of London’s Imperial College with some 25 years

of experience in solving engineering problems. After graduating he

joined Rolls Royce where he attained chartered status with the Institute

of Mechanical Engineers. Having risen to the position of Chief

Mechanical Engineer with Bombardier Transportation he started his own

engineering consultancy in 1995 called MoreVision. It specialises in

engineering analyses applied to railway vehicles, construction

equipment, oil and gas plant, cranes and mechanical items for theme

parks. His client list includes Shell, Bombardier, Siemens, Volvo and

Disney. He won a UK Government SMART competition for software innovation

and his website attracts over 18,000 unique visitors every month.

LOCATION: Courses can be arranged at our site, your site or at a convenient hotel.

TRAINING PROVIDERS: We work with other training providers should they want to add this course to their training schedule.

A two day training course designed to help practising engineers understand and avoid fatigue failure in welded structures. Download the course brochure and syllabus here.

A two day training course designed to help practising engineers understand and avoid fatigue failure in welded structures. Download the course brochure and syllabus here.

SUMMARY: The course uses real world case studies to understand the engineering principles governing fatigue failure of welded structures. We reduce complex mathematics to simple hand calculations using Excel workbooks so that engineers at all levels can understand the concepts covered. Engineers will leave understanding how to apply the AWS rules for fatigue design and will pick up new engineering and Excel skills along the way. Our YouTube video to outlines the course – it focuses on American AWS methods of fatigue assessment but the material equally covers BS7608 and Eurocode methods.

A two day training course designed to help practising engineers understand structural design. Download the course brochure and syllabus here.

A two day training course designed to help practising engineers understand structural design. Download the course brochure and syllabus here.

SUMMARY: We take real world examples and failure case studies to understand the engineering principles governing the structural integrity. We reduce complex mathematics to simple hand calculations using Excel workbooks so that engineers at all levels can understand the concepts covered. Attendees will learn how to size structural members and how to weld and bolt them together to build engineering structures.

"

Mathematical Modelling for Engineers

" is a 2 day training course designed to help practising engineers understand and avoid common engineering failures and quantify technical risk. It is scheduled to start in February 2011. Download the course brochure and syllabus here.

"

Mathematical Modelling for Engineers

" is a 2 day training course designed to help practising engineers understand and avoid common engineering failures and quantify technical risk. It is scheduled to start in February 2011. Download the course brochure and syllabus here.

SUMMARY: A mathematic model is a description of a system using numerical logic. Once constructed a model shows how a system responds to change and gives you a tool to assess risk, to optimise and to innovate. Copying from a library of solutions learn how to build models quickly to cover any engineering system and support technical decisions. Attendees have access to the library, and other resources, both during and after the course. We avoid use of specialist software and only assume that attendees have Microsoft Excel (any version). Discover little known Excel techniques and best practise for mathematical modelling. We take real life examples from theme parks case studies to showcase common engineering elements like structures, connections and machine components. Attendees work together to build their own rollercoaster and manage their new attraction to avoid engineering failure scenarios.

WHO SHOULD ATTEND: The course is intended for practising engineers of any discipline (civil, structural and mechanical) particularly those involved with design, service provision and engineering management.

|

Design of Aluminium Rail Vehicles

Taiwan Railway Industry - A group of 18 engineers in Taiwan consisting engineers from government and industry had a particular interest in 'Design of Aluminium Railway Vehicles'. Aluminium designs offer up to a 30% weight saving and reduced manufacturing costs over conventional steel designs. Topics covered include metallurgy and comparison with steel, history of aluminium rail vehicles, design and manufacturing requirements and constraints, finite element analysis, weld design, fatigue design and analysis, mechanical fastening and analysis of preloaded joints, crashworthiness and structural testing. The 5 day course combines presentations, videos, tutorials, quizzes and practical workshops. All course materials are accessible by the internet. Certificates of completion are issued after satisfactory completion of the course examination. Choosing from modules below, a 5 day course was assembled to meet their specific needs. You can see the participants being awarded their certificates opposite. I had a wonderful time in Taipei thanks to generous hospitality of my clients.

Taiwan Railway Industry - A group of 18 engineers in Taiwan consisting engineers from government and industry had a particular interest in 'Design of Aluminium Railway Vehicles'. Aluminium designs offer up to a 30% weight saving and reduced manufacturing costs over conventional steel designs. Topics covered include metallurgy and comparison with steel, history of aluminium rail vehicles, design and manufacturing requirements and constraints, finite element analysis, weld design, fatigue design and analysis, mechanical fastening and analysis of preloaded joints, crashworthiness and structural testing. The 5 day course combines presentations, videos, tutorials, quizzes and practical workshops. All course materials are accessible by the internet. Certificates of completion are issued after satisfactory completion of the course examination. Choosing from modules below, a 5 day course was assembled to meet their specific needs. You can see the participants being awarded their certificates opposite. I had a wonderful time in Taipei thanks to generous hospitality of my clients.

ExcelCalcs Training Module (1/2 day) - Learn how to o ur XLC software with MS Excel so that cell formulae can be displayed as mathematical equations. Now that cell formulae can be checked directly against mathematical expressions you'll never insert an incorrect cell formula again! A free copy of the software will be given to each participant and you'll be given a guided tour of the Repository.

Design of Welded Joints Module (1 day) - Learn how to weld steel and aluminium joints and avoid problems associated with joint strength, and joint fatigue cracking.

Failure Investigation Module (1 day) - What happens when something breaks in service? How do we understand what has happened? How do we mitigate against future failures? How do we make sure it never happens again? |

Design of Construction Equipment

The ‘Design of Construction Equipment’ is a 5 day course last delivered in the beautiful town of Belley in the French Alps. Twelve engineers from Volvo travelled from France, Poland, Germany and India to attend the 5 day course. Volvo had selected a number of ExcelCalcs training modules plus asked me to write some specifically for Volvo. I was pleased to receive some very positive feedback for both the training and XLC. The attendees expressed how XLC spreadsheets helped to explain the physical principles without getting bogged down by the maths. Understanding is gained (and retained) by observing the effect of changing input parameters. Monday

Tuesday

Wednesday

Thursday

Friday

The ExcelCalcs Day-Tripper Course

Don't forget the Day-Tripper courses. This is a great option for all those people who say “Yeah ExcelCalcs and XLC look great… but I am too busy to learn”. Sign up for the ExcelCalcs tour and we'll get you up and running with XLC and show you around the best content on the site in a single day. You can arrange for a private group from your own organisation or you can attend one of our scheduled events. If you represent a group people and would like a private tour email to discuss. Don't forget the Day-Tripper courses. This is a great option for all those people who say “Yeah ExcelCalcs and XLC look great… but I am too busy to learn”. Sign up for the ExcelCalcs tour and we'll get you up and running with XLC and show you around the best content on the site in a single day. You can arrange for a private group from your own organisation or you can attend one of our scheduled events. If you represent a group people and would like a private tour email to discuss.

|