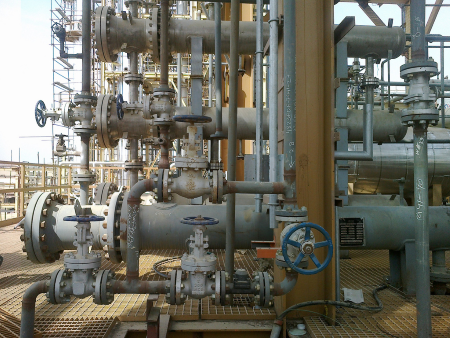

Piping

0 ContainersFiles in Piping

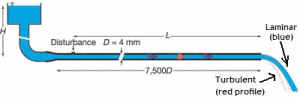

AirFlow

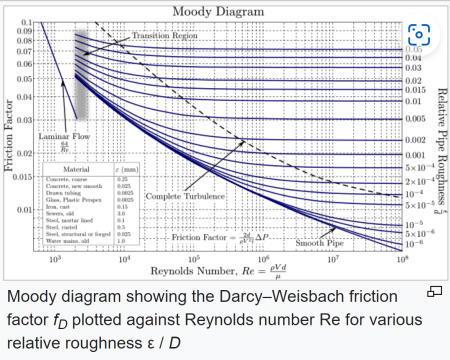

Calculates the Moody friction factor and then the head loss and pressure drop per classic equations.

Enter temper...

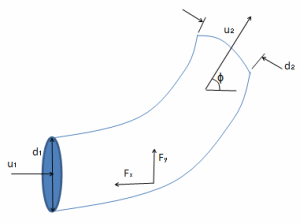

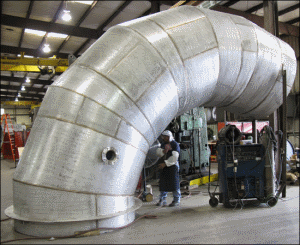

ASME CALCULATION FOR MITER BEND

Calculation Reference

ASME

Piping Design

Piping Design Codes

The American Society of Mechanical Engineers (AS...

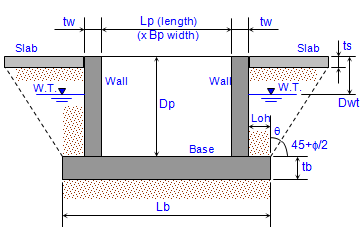

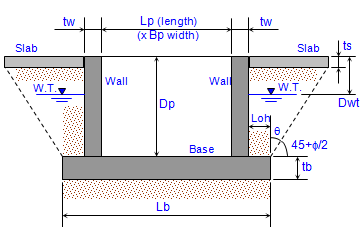

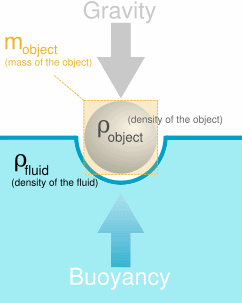

Buoyancy control analysis

CALCULATION FOR SET ON WEIGHT Pipe size Outside diameter, OD Wall thickness, t Weight of pipe, WP Density of water, r Buoya...

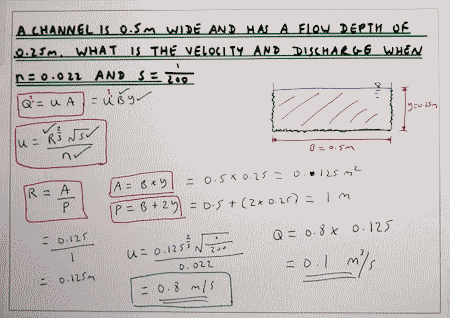

Colebrook_White.xls

Purpose of calculation: To determine the Velocity & Flow of water through pipes of varying diameter, slope & material. Calculation Reference:...

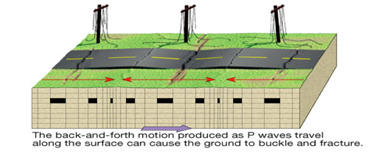

DKE_PipingVibration_MainLines.xlsx

EI Guidelines for the Avoidance of Vibration - TM-01 Qualitative Assessment

Energy Institute Guideline...

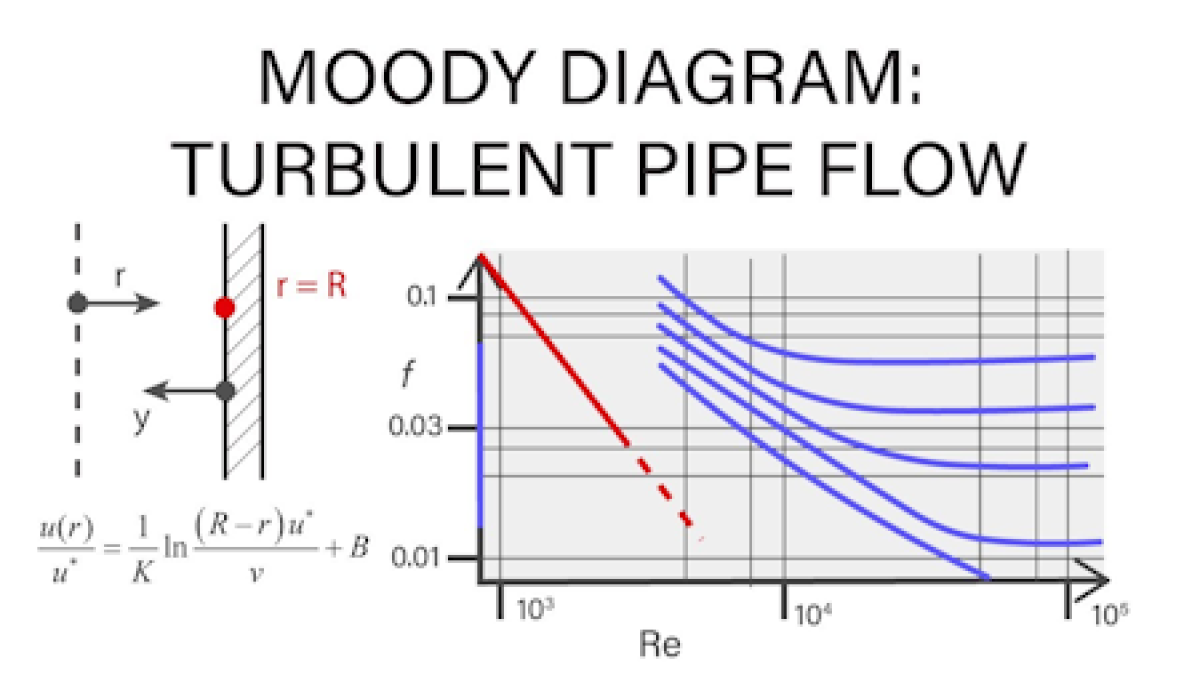

Pipe flow/friction factor calculations

Calculation of Head Loss and Frictional Pressure Drop for given flow rate, pipe diameter, pipe length, pipe roughness, fluid density & viscosity, ...

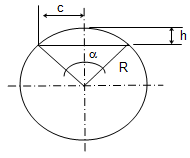

PIPESPANS V1

PIPESPANS is a spreadsheet program written to determine the maximum stress and deflection of a pipe. Stress and deflection are calculated as funct...

PSV relief sizing

This spreadsheet calculates the required effective discharge area of a pressure safety valve. To calculate the required effective disc...

Recommended Span Length

This spreadsheet is calculating recommended pipe support spacing for piping systems - essentially determining how far apart you can place pipe supp...

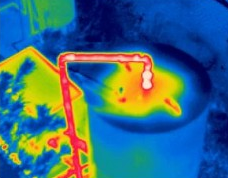

Thermal Expansion

This sheet is a very simple and quick way to calculate linear thermal expansion in typical metal piping materials. Also valid for non-piping compon...

Vibration within piping downstream of high pressure cut control valves and regulators

This one calculates and assess vibration within piping downstream of high pressure cut control valves and regulators and then recomme...

Wall Thickness Calc

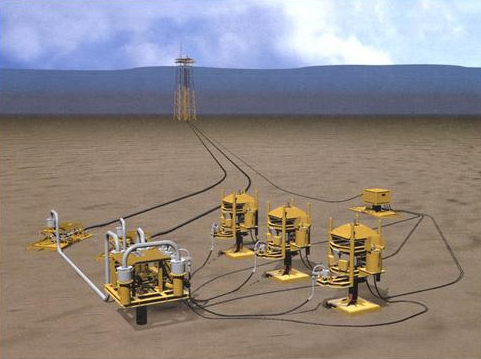

Pipe wall thickness calc according to

Calculation Reference Subsea Piping

Offshore Pipes

API RP 1111

API RP 1111...

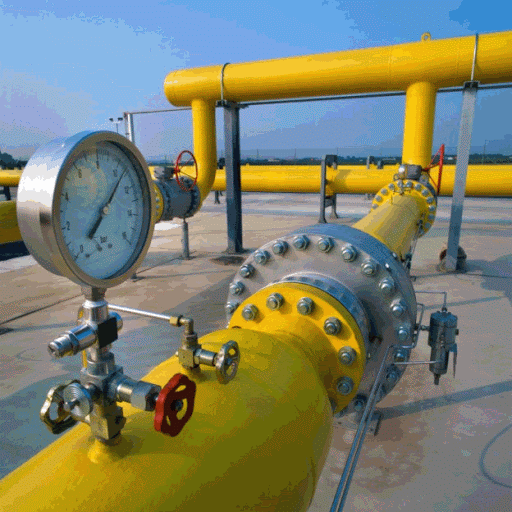

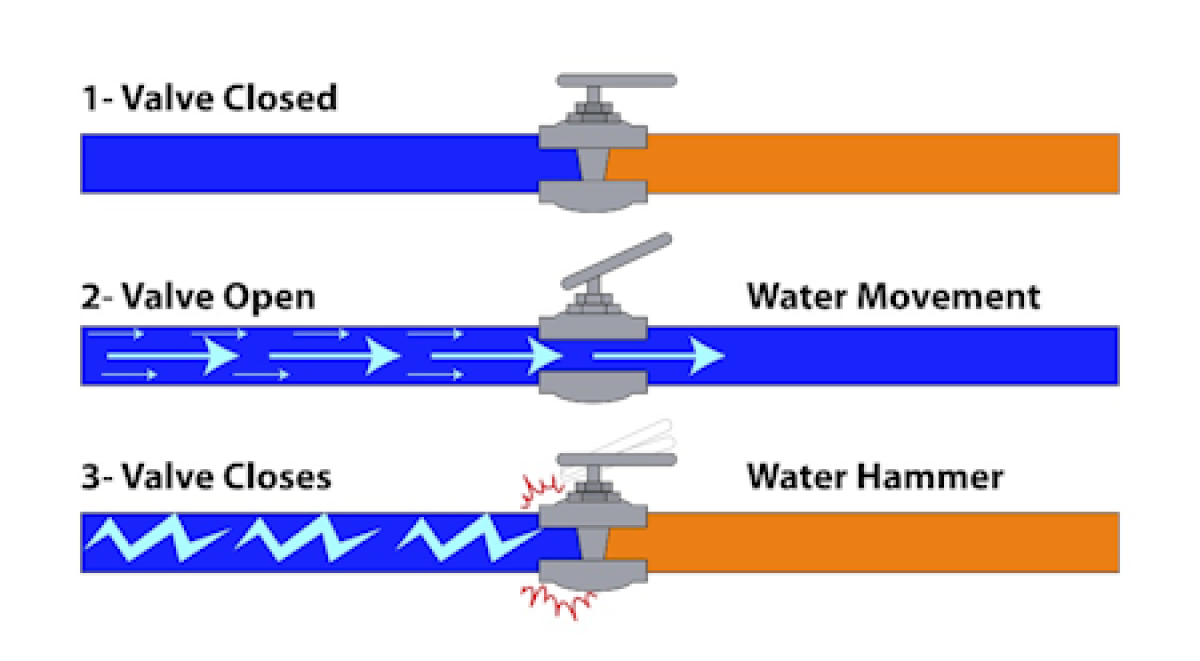

Water Hammer Pressure Calculator

Water hammer is a fluid mechanics phenomenon that occurs in piping systems when the flow of liquid is suddenly stopped or changed direction. This c...