Welds

0 ContainersFiles in Welds

Aluminum Design Manual Welding

Uses rules and properties from the Aluminum Design Manual to size different welds. Includes many types of aluminum base and...

gowelding.com Weld Calculations

Note: this is simply a link to a site which I have found to be a very useful reference. You should follow this link to access the site directly ...

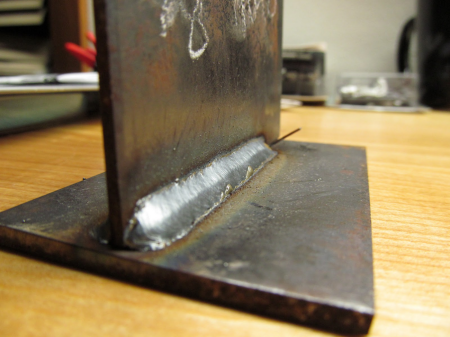

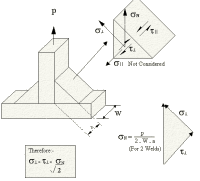

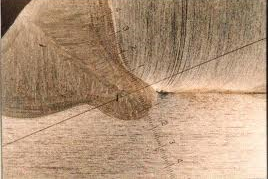

Plate Stress to Fillet Weld Stress

Calculate fillet weld stress from parent plate stresses

Calculation Reference First principles

To calc...

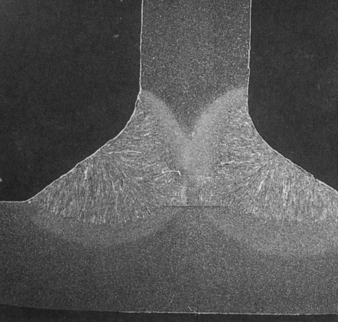

Plate Stress to Partial Penetration Fillet Weld Stress

Calculate weld throat stress from plate bending, direct and shear stresses. It is useful for detailed stress analysis of welded connectio...

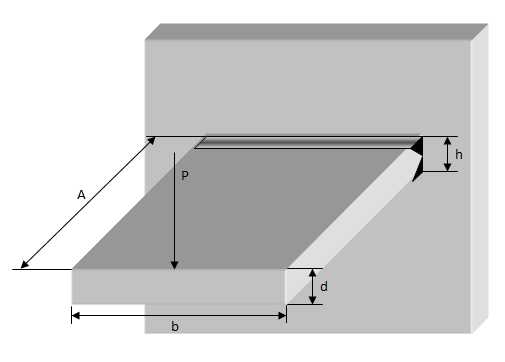

Static load capacity of the parallel loaded fillet welds.xls

KNOWN: Two statically loaded plates of known strength are fillet-welded together with specified weld geometry and weld strength.

FIND:...

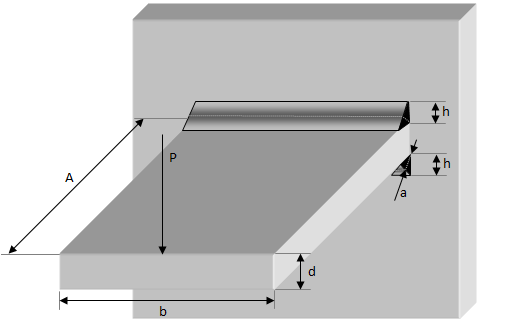

Static load capacity of the transverse-loaded fillet welds.xls

KNOWN: Two statically loaded plates of known strength are fillet-welded together with specified weld geometry and weld strength.

FIND:...

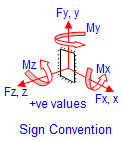

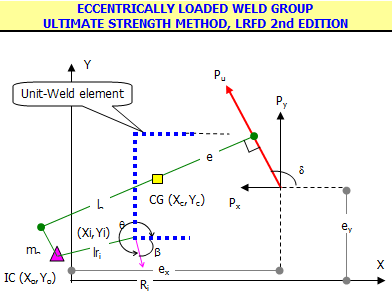

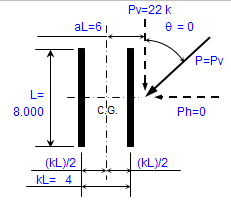

Weld Check

Weld Check is a spreadsheet program written in MS-Excel for the purpose of analysis of 2D weld groups using the 'elastic' (vector) method. ('Altern...

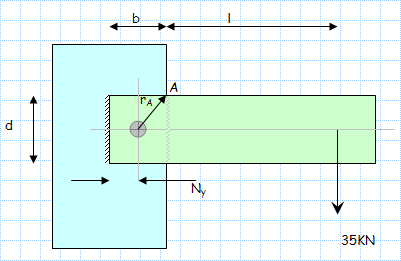

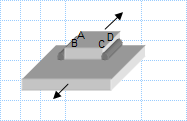

Weld line assessment - 2 horizontal welds.xls

The method of assessing fillet welds groups treating welds as lines is reasonably safe and conservative and is very convenient to use.

...

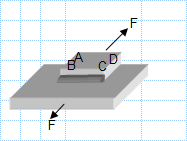

Weld line assessment - C shaped.xls

The method of assessing fillet welds groups treating welds as lines is reasonably safe and conservative and is very convenient to use.

a)...

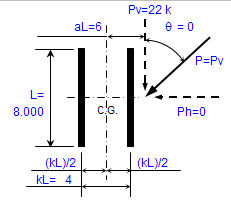

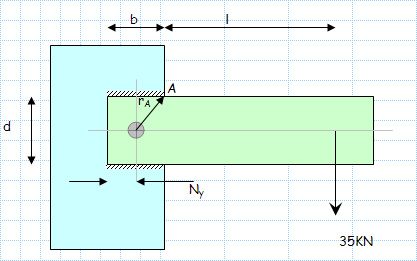

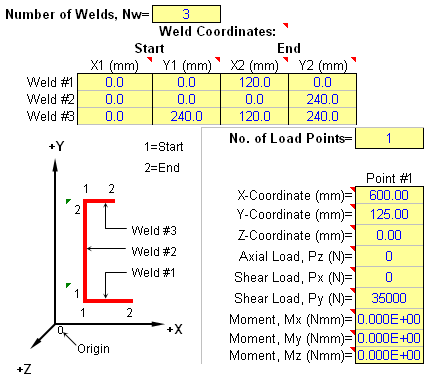

WELDGRP Metric.xls

This is a reworking of Alex Tomanovich's spreadsheet 'WELDGRP.XLS' It has reworked for metric units.

It includes an verification ...