Areas

0 ContainersFiles in Areas

Order by

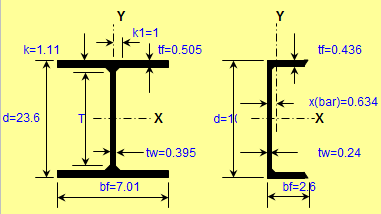

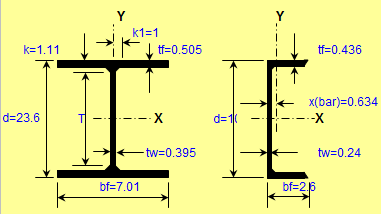

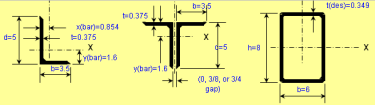

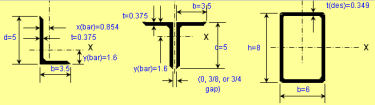

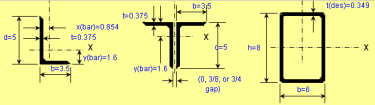

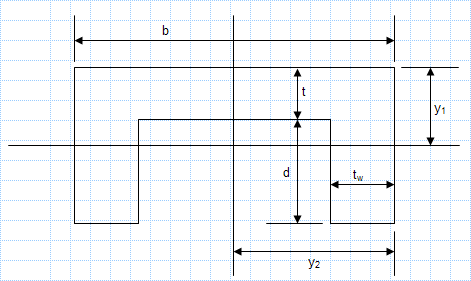

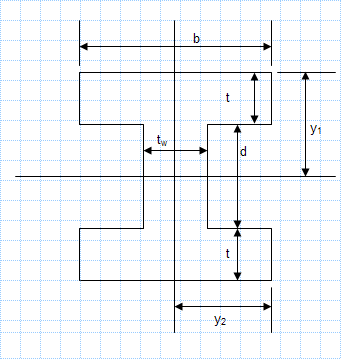

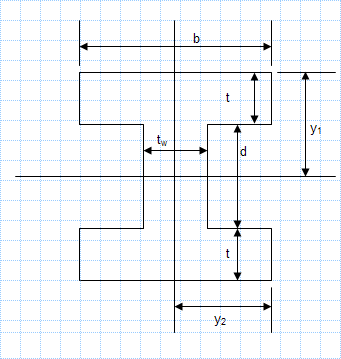

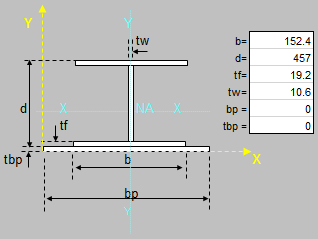

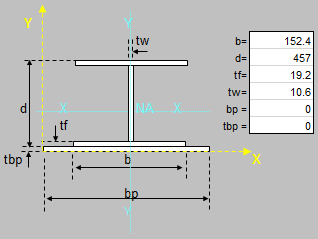

Beam/Column and Beam+Column Section Classes per AISC 360 and CSA S16

Short Description:

As you know, the calculations for beams, columns and beams plus columns are based on different equations per AISC 360 and CSA S16. These two worksh...

Submitted By:

Last Modified

19 Apr 2021

Downloads:

63

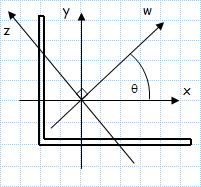

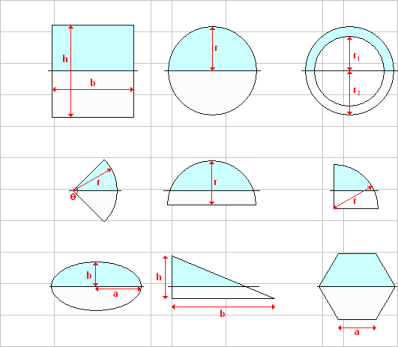

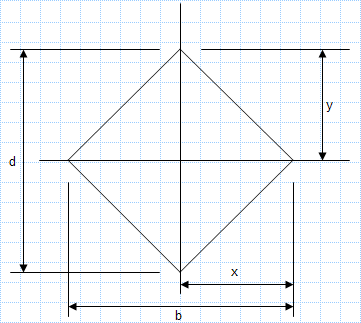

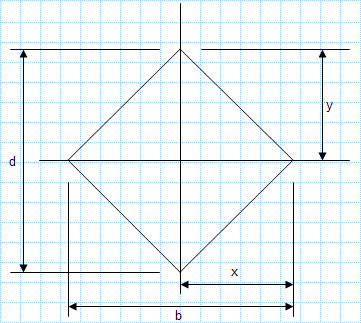

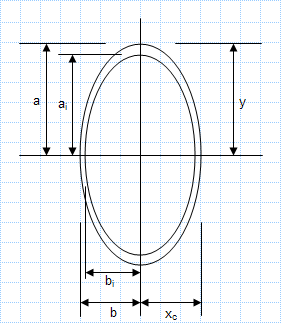

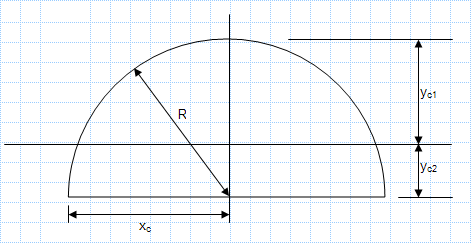

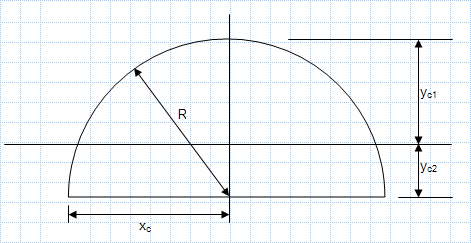

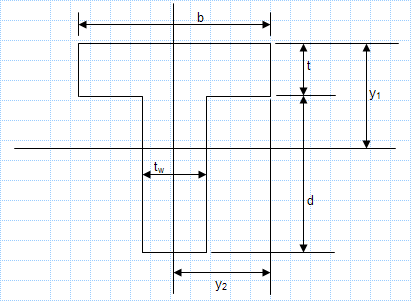

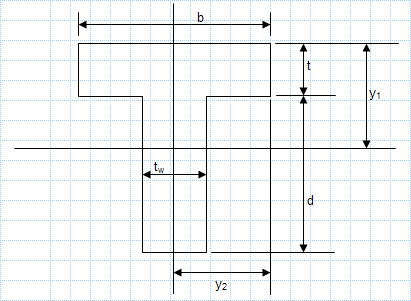

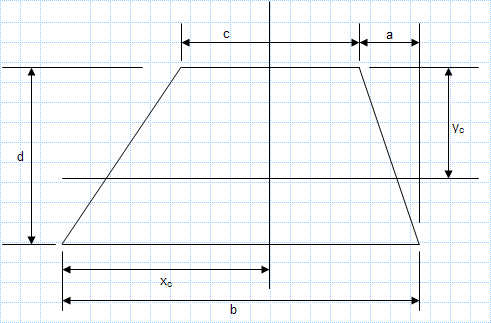

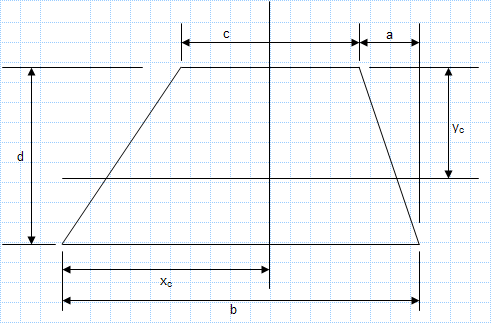

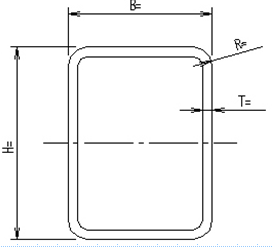

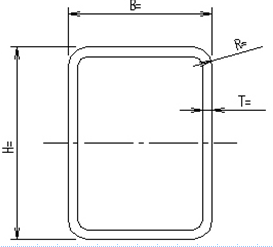

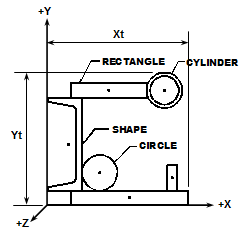

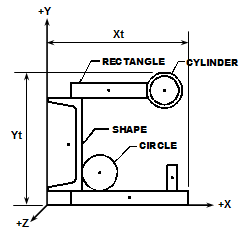

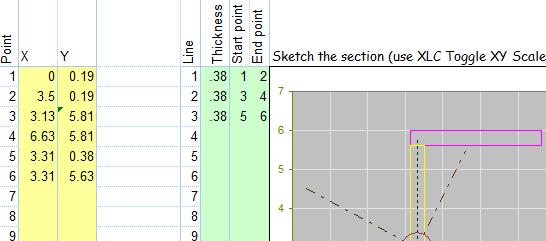

General Section Properties & Stresses

Short Description:

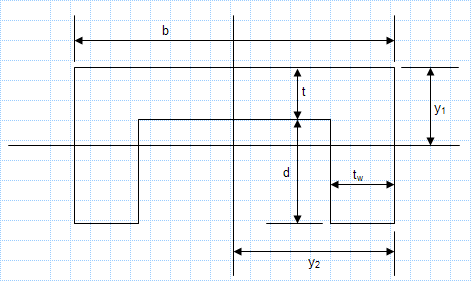

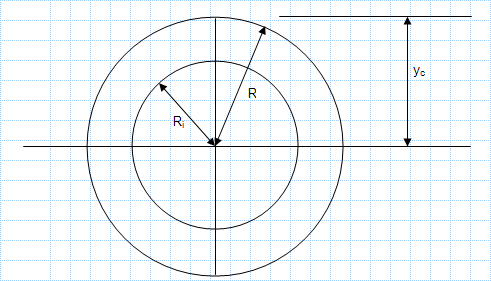

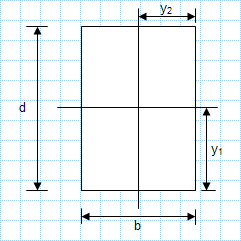

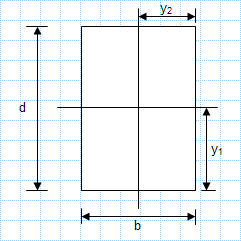

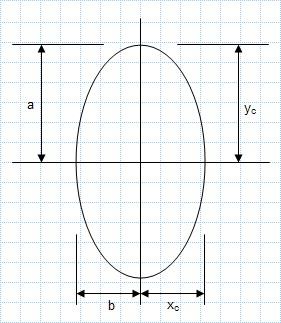

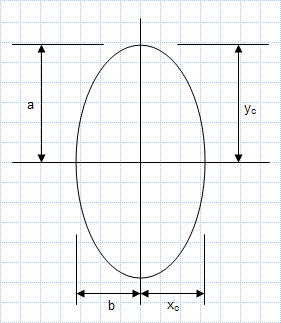

This spreadsheet calculates the section properties of a general shape defined by nodal co-ordinates together with the stress ...

Submitted By:

Last Modified

28 Jul 2014

Downloads:

163

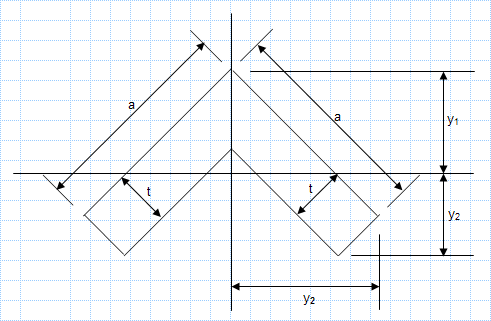

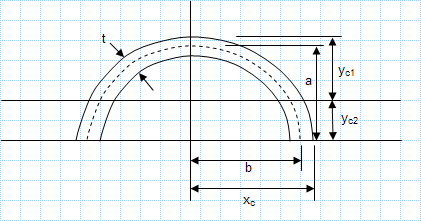

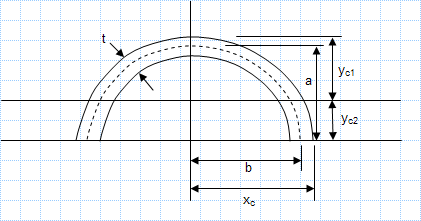

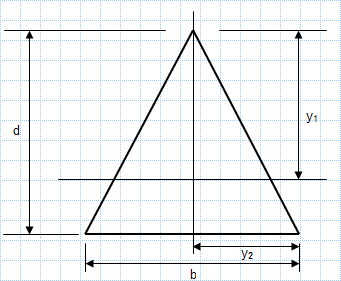

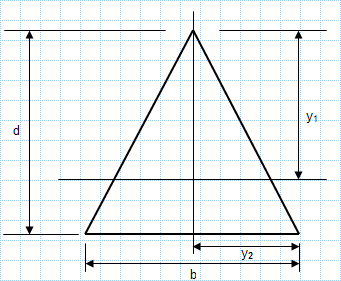

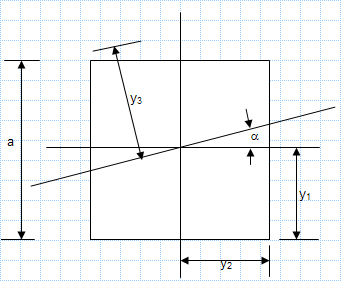

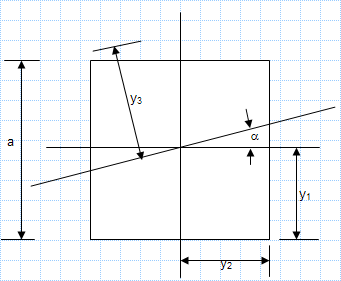

LineSec.xls

Short Description:

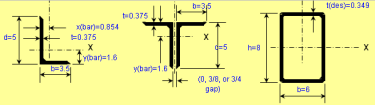

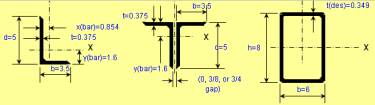

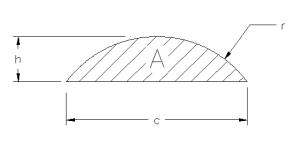

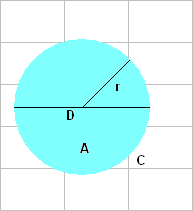

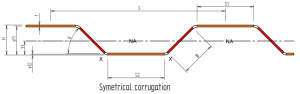

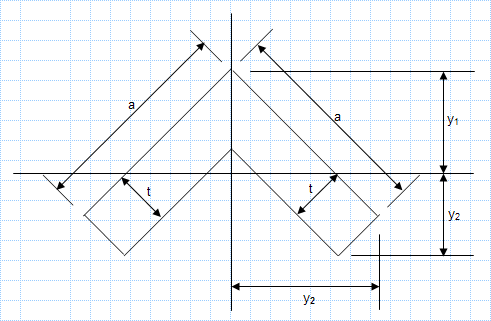

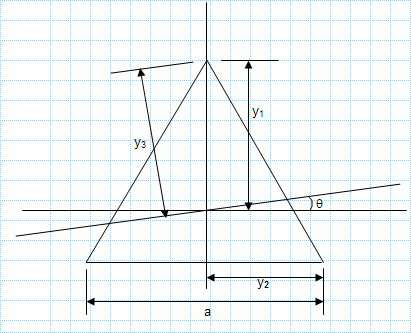

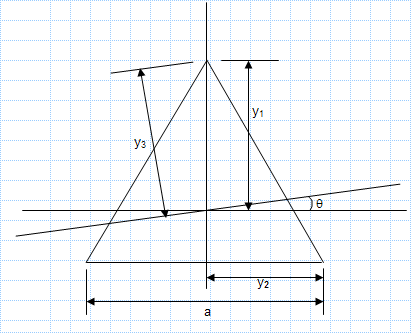

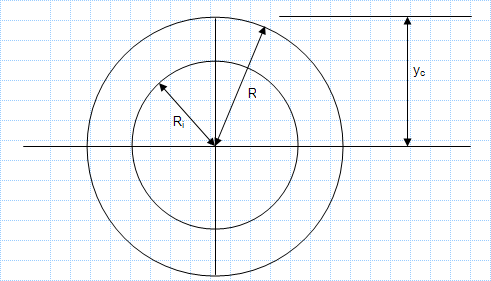

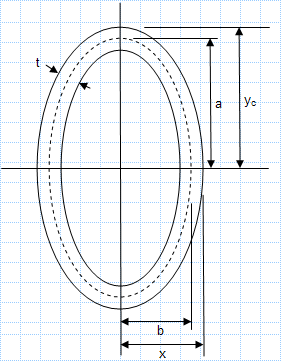

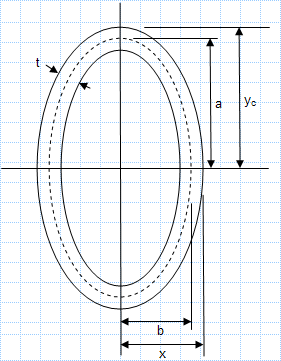

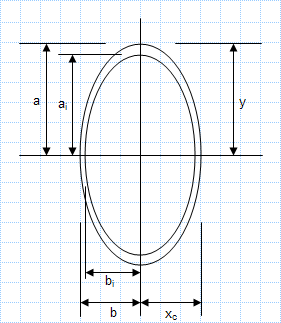

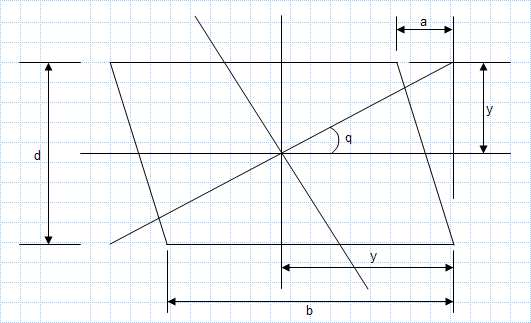

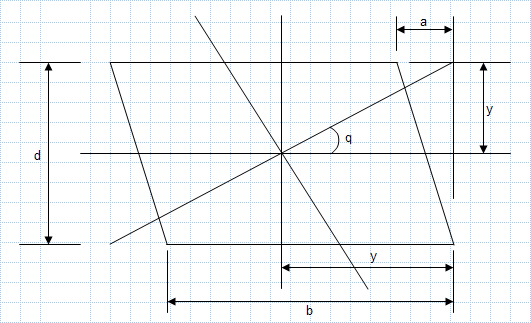

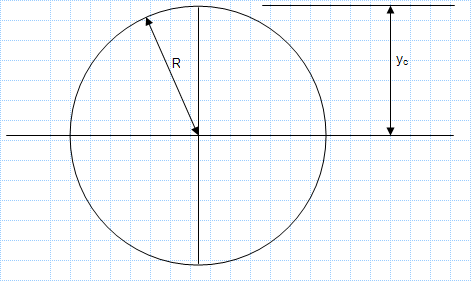

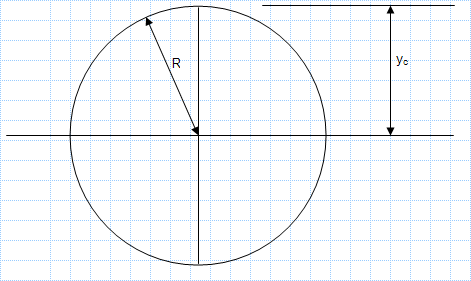

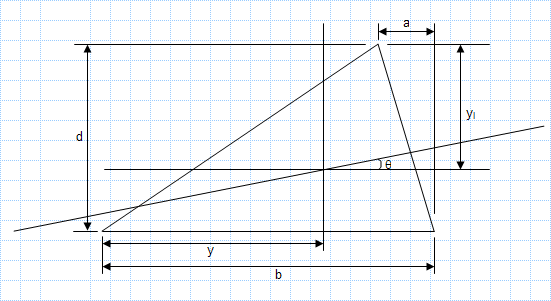

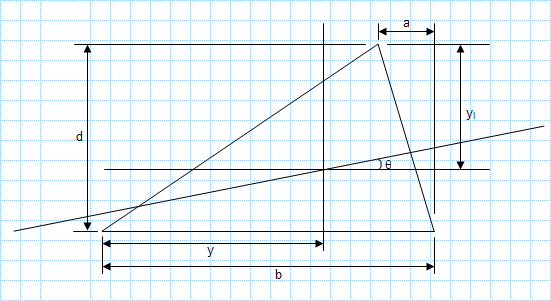

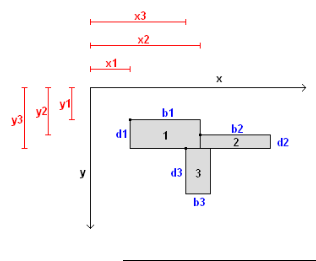

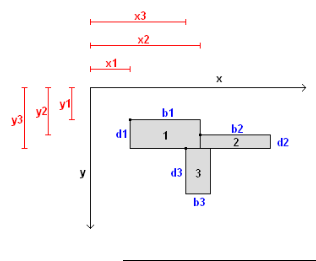

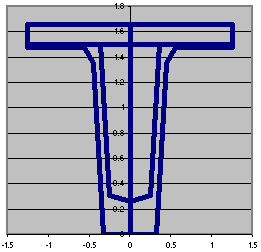

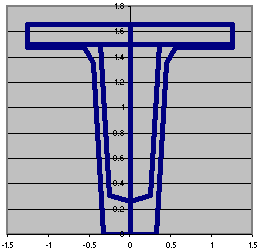

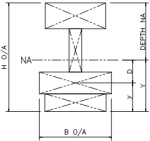

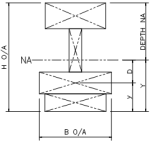

'LINESEC' - SECTION PROPERTY CALCULATION FOR SECTIONS DEFINED BY LINES

Program Description: 'LI...

Submitted By:

Last Modified

31 May 2011

Downloads:

208

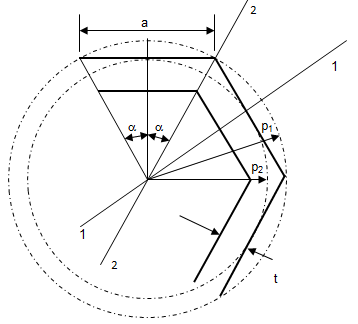

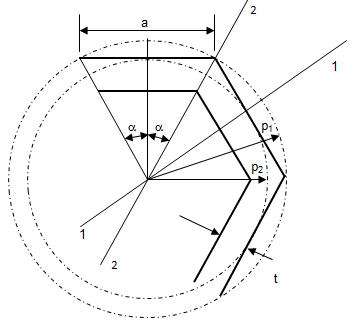

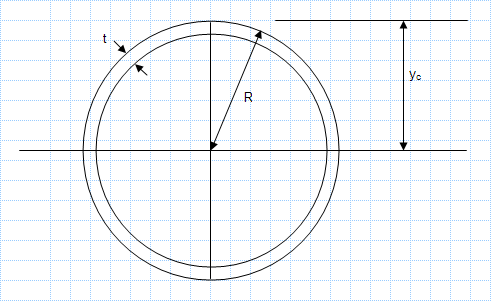

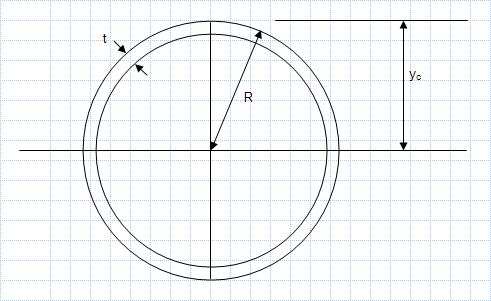

pipe strength base on API 5L

Short Description:

Calculate pipe strength in two ways: stress and force,base API 21th wsd.

Calculation Reference

Pipe Design

Secti...

Submitted By:

Last Modified

24 Sep 2013

Downloads:

95