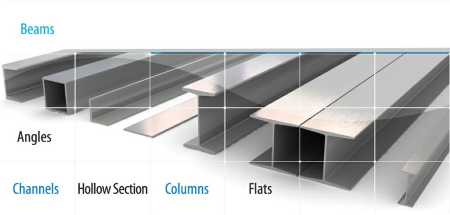

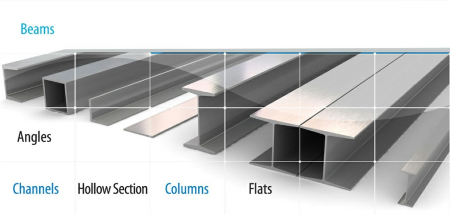

Beams

0 ContainersFiles in Beams

Order by

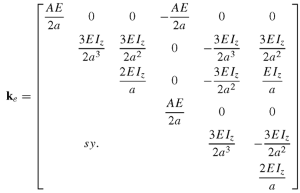

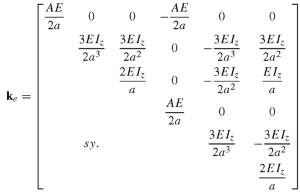

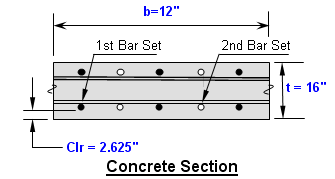

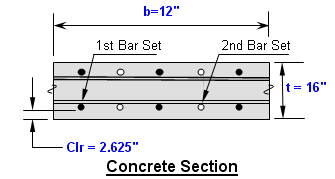

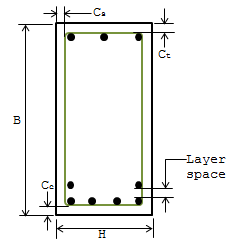

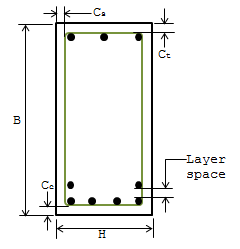

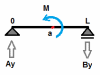

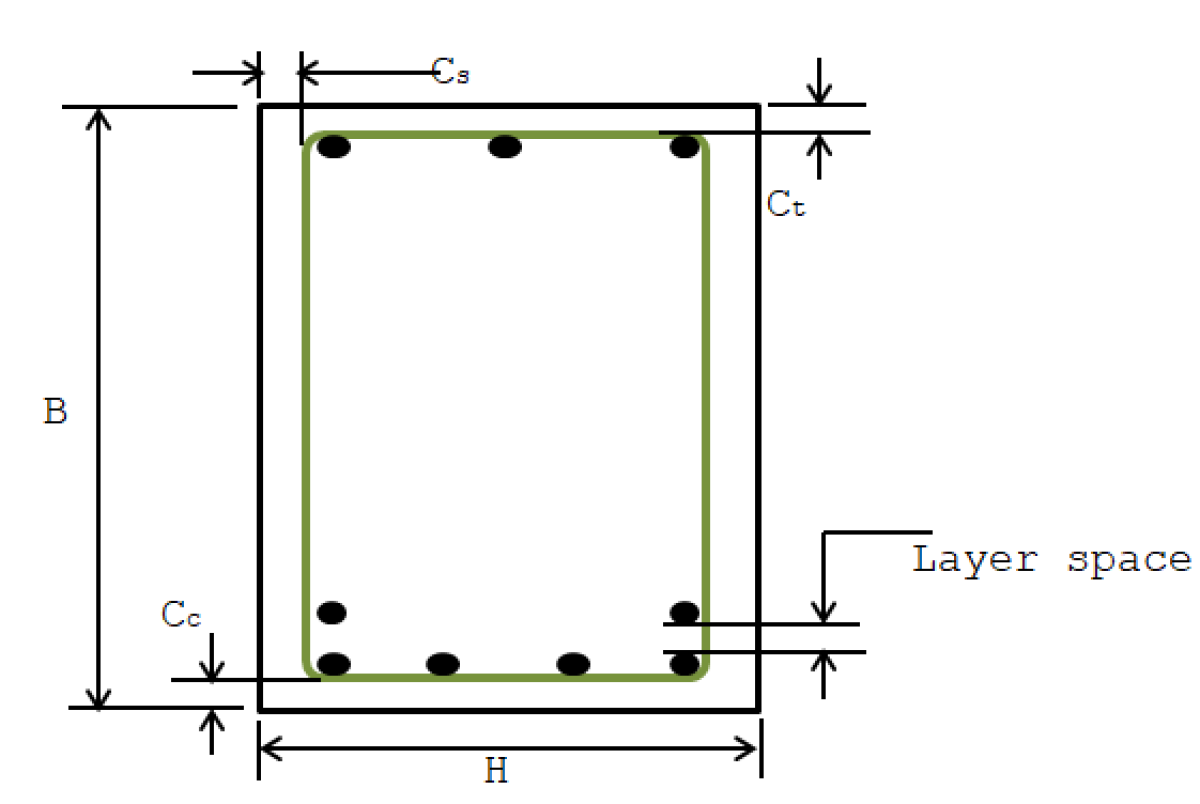

ANALYSIS & DESIGN OF RC BEAM AS PER ACI 318-08

Short Description:

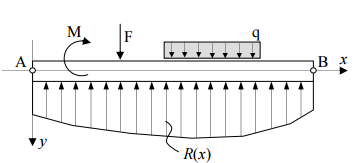

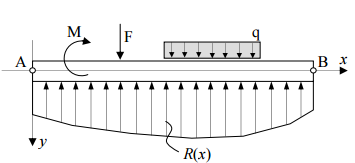

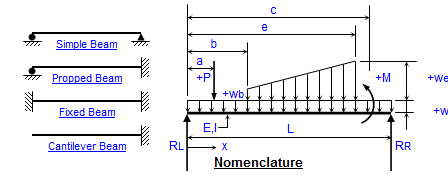

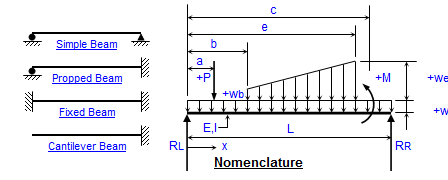

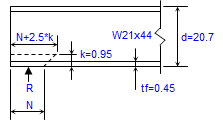

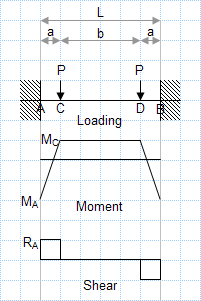

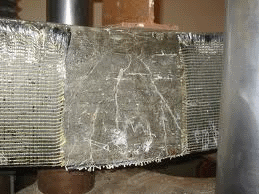

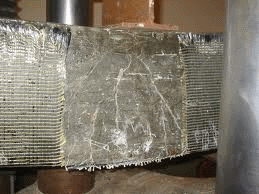

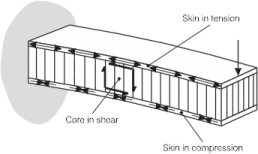

The Basic Concept: When a concrete beam bends under load, the concrete on one side gets compressed while the other side gets stretched (tension). S...

Submitted By:

Last Modified

06 Aug 2020

Downloads:

4

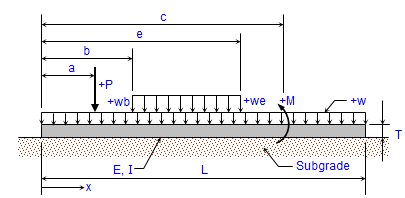

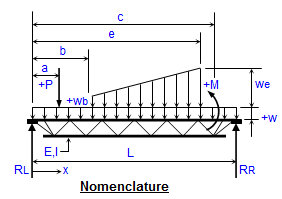

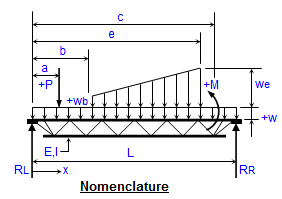

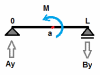

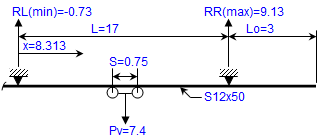

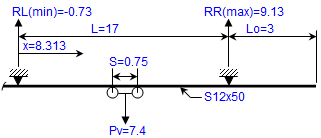

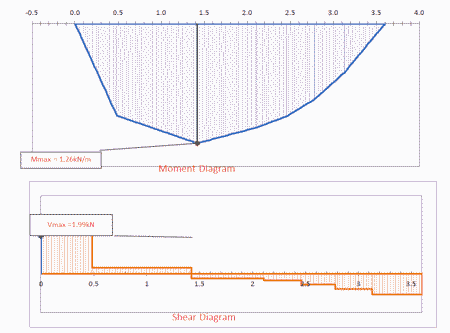

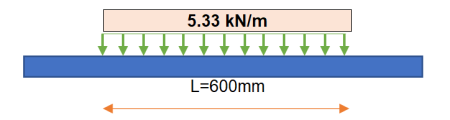

Equialent UDL from Point Loads in Beam

Short Description:

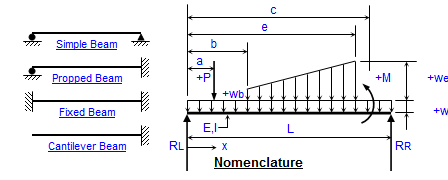

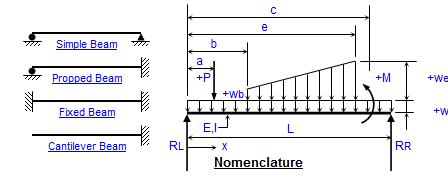

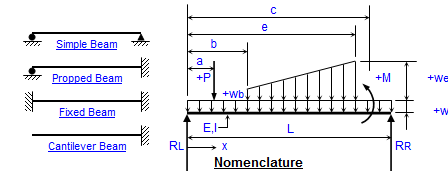

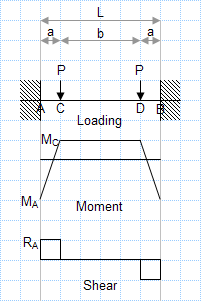

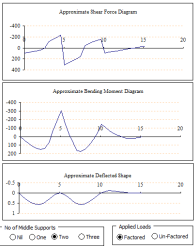

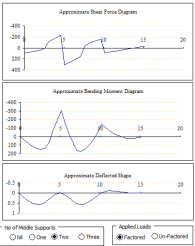

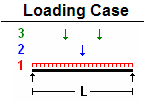

Calculating the equivalent distributed load from a set of point loads in a beam can be highly beneficial to an engineer for several reasons...

Submitted By:

Last Modified

13 Mar 2024

Downloads:

19

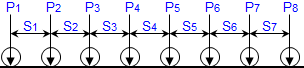

Loading Calculation Sheet.xlsx

Short Description:

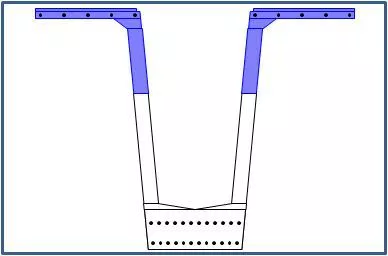

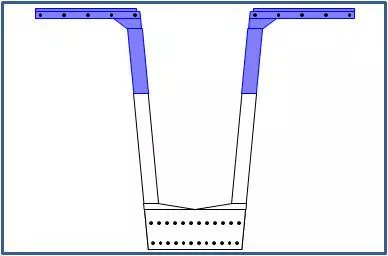

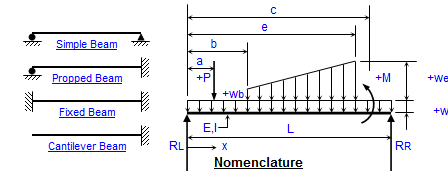

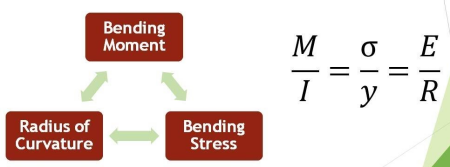

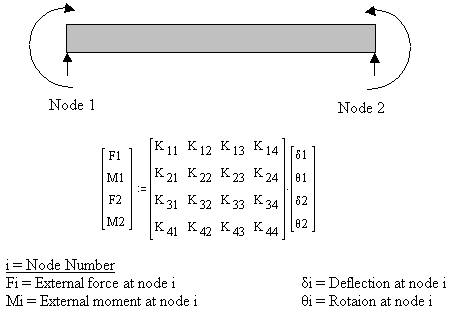

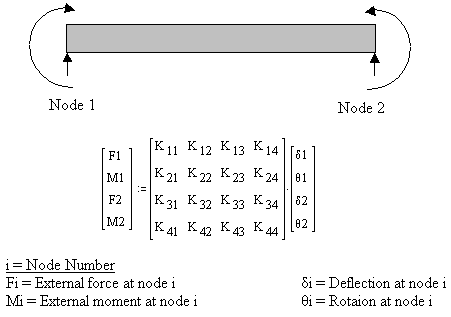

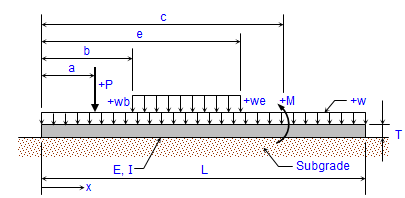

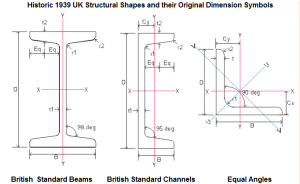

Beam bending theory is a fundamental concept in structural engineering and solid mechanics that deals with the deformation and stress distr...

Submitted By:

Last Modified

02 Jan 2023

Downloads:

19