Civil Engineering

0 ContainersFiles in Civil Engineering

Order by

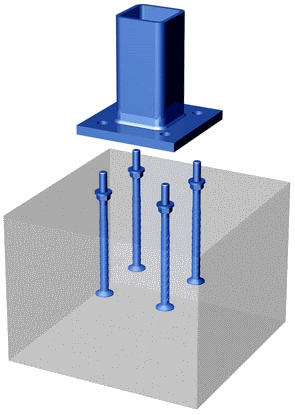

AISC 2016 Base plate calculation _DG-01

Short Description:

The AISC (American Institute of Steel Construction) 2016 specification provides guidelines for the design and construction of structural steel buil...

Submitted By:

Last Modified

21 Jan 2022

Downloads:

119

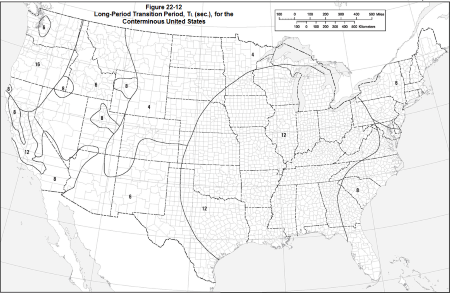

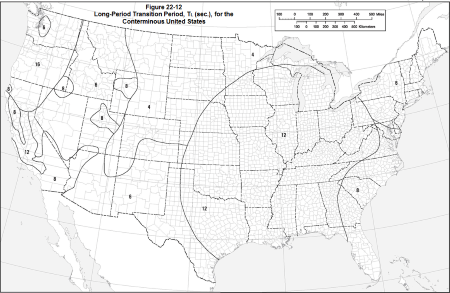

ASCE710W - ASCE 7-10 CODE WIND ANALYSIS PROGRAM

Short Description:

ASCE 7-10, 'Minimum Design Loads for Buildings and Other Structures,' is a standard developed by the American Society o...

Submitted By:

Last Modified

15 Mar 2023

Downloads:

1189

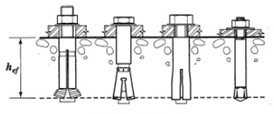

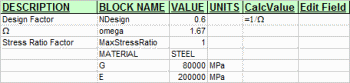

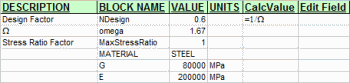

Base Plate Design (Biaxial Bending) - AISC 360-16 LRFD

Short Description:

The MS-Excel spreadsheet program designed for the analysis of steel column base plates serves as a comprehensive engineering tool catering ...

Submitted By:

Last Modified

10 Nov 2023

Downloads:

202

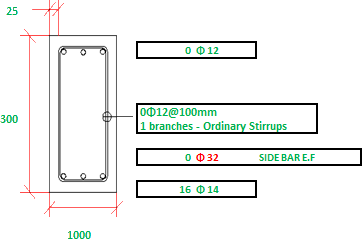

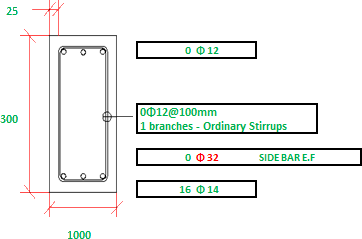

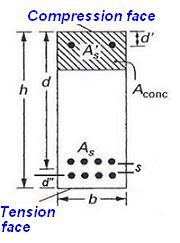

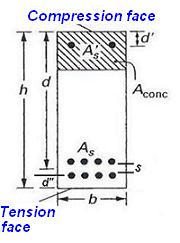

Base Slab and Crack Width

Short Description:

ACI 318-11 Crack Width Calculations For Slab. 1 - Locate the Neutral axis & Calculate section properties: 2 - Check of Concrete &...

Submitted By:

Last Modified

11 Sep 2019

Downloads:

105

Calculation of Modulus of Subgrade Reaction

Short Description:

Modulus of subgrade reaction or coefficient of subgrade reaction is the reaction pressure sustained by the soil sample under a rigid plate of s...

Submitted By:

Last Modified

26 Oct 2021

Downloads:

123